Main Menu

DC gear motors are revolutionizing the way we approach efficiency and performance in various applications, from robotics to electric vehicles. A report by MarketsandMarkets predicts that the global DC gear motor market will grow from $3.1 billion in 2021 to $4.1 billion by 2026, at a compound annual growth rate (CAGR) of 5.7%. This growth is driven by the increasing demand for energy-efficient devices and the rising need for automation across multiple industries.

As the adoption of DC gear motors expands, understanding their operational efficiencies, torque characteristics, and performance metrics becomes crucial for engineers and designers. This comprehensive guide provides valuable insights and tips for maximizing the potential of DC gear motors, ensuring they meet the escalating demands of modern technology. By leveraging the latest advancements and industry best practices, users can unlock unparalleled performance while optimizing energy consumption and overall system reliability.

As the adoption of DC gear motors expands, understanding their operational efficiencies, torque characteristics, and performance metrics becomes crucial for engineers and designers. This comprehensive guide provides valuable insights and tips for maximizing the potential of DC gear motors, ensuring they meet the escalating demands of modern technology. By leveraging the latest advancements and industry best practices, users can unlock unparalleled performance while optimizing energy consumption and overall system reliability.

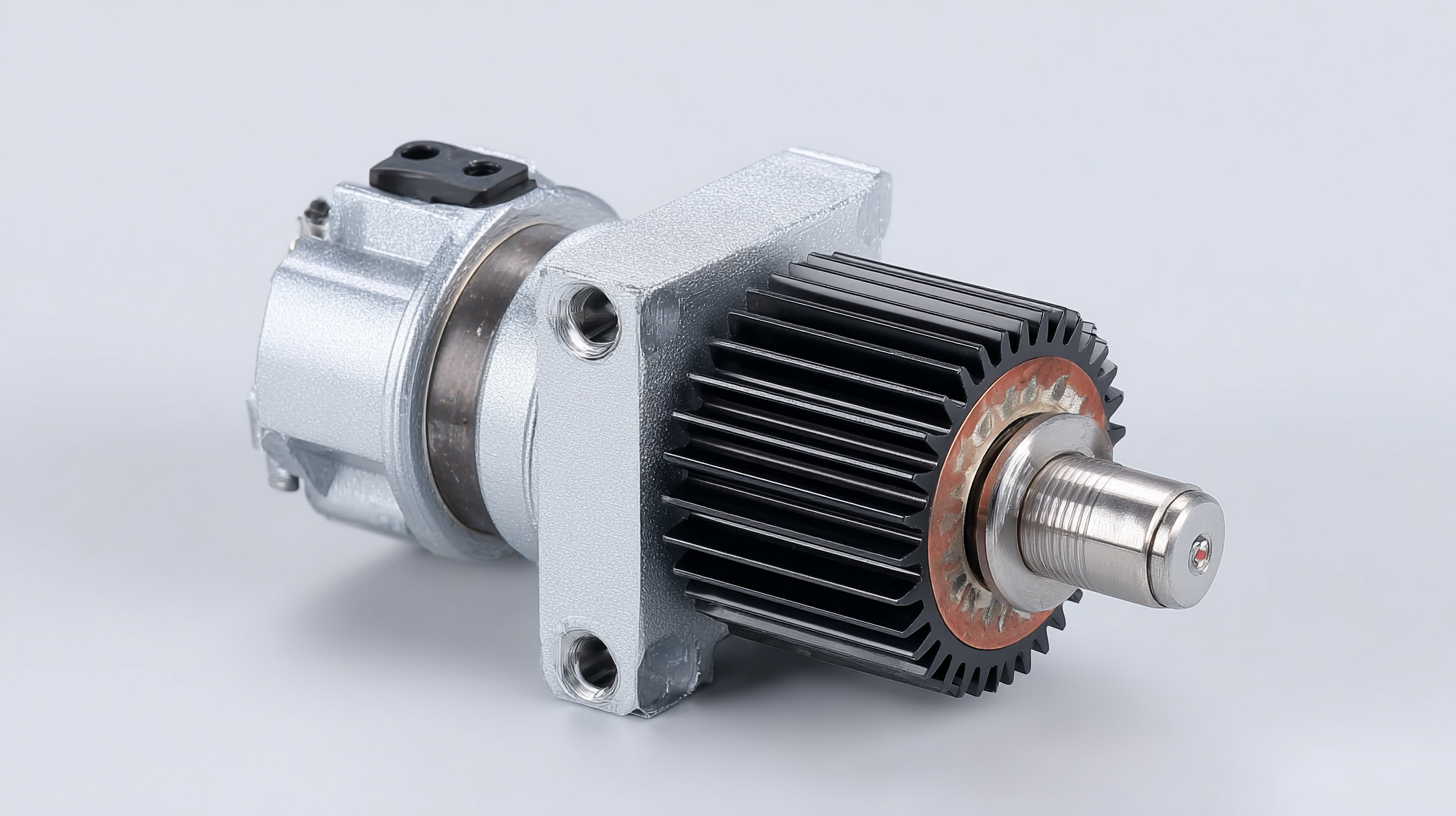

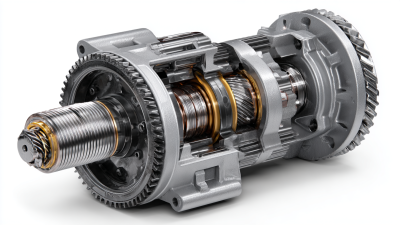

DC gear motors are essential components in various applications, integrating efficiency and performance to drive machinery effectively. Understanding their construction and operation principles is crucial. A typical DC gear motor consists of a direct current (DC) motor and a gear train, which together provide the necessary torque and speed reduction. The gear reduction enables the motor to achieve higher torque at lower speeds, making it ideal for applications that require precision movement, such as in robotics and automation.

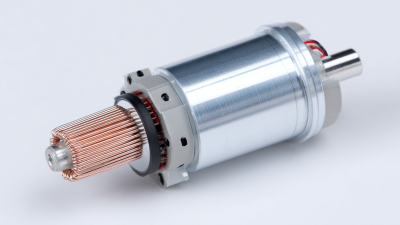

The operational principle of DC gear motors revolves around electromagnetic induction, where an electric current flows through a coil, generating a magnetic field that interacts with the permanent magnets in the motor. This interaction causes the rotor to rotate, converting electrical energy into mechanical energy. Recent advancements, such as the development of brushless DC motors, have minimized issues like noise and vibration, enhancing overall performance. This innovation highlights the ongoing evolution in electric motor technology, making it increasingly accessible for various industrial applications.

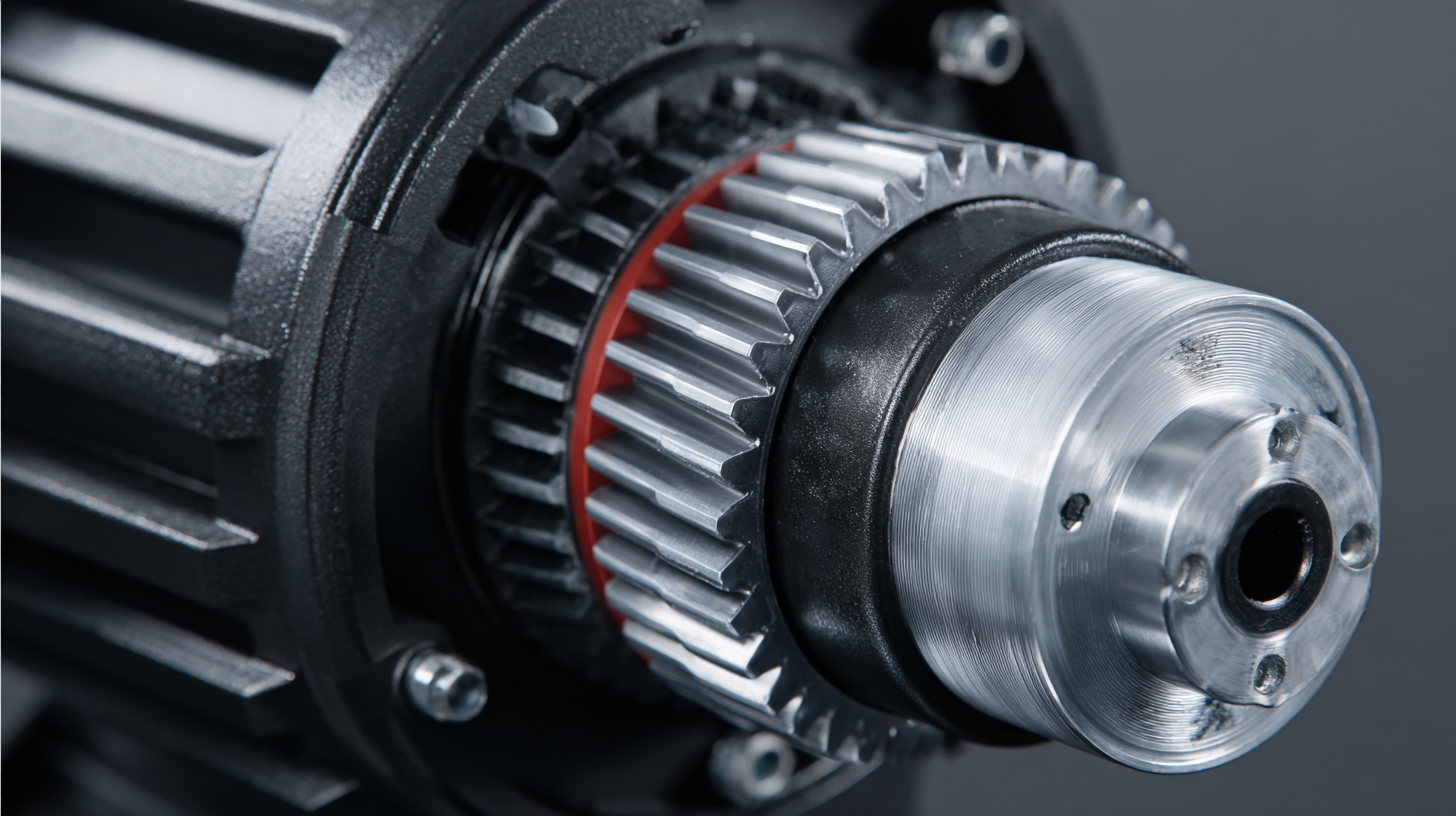

When evaluating the efficiency of DC gear motors, several key performance metrics stand out as essential for assessing their overall effectiveness. One of the most significant metrics is the motor’s efficiency rating, typically expressed as a percentage that represents the ratio of mechanical output power to electrical input power. According to a report by the International Electrotechnical Commission (IEC), the efficiency of high-quality DC gear motors can range from 75% to 90%, depending on the design, size, and load conditions. This high efficiency not only translates to reduced energy consumption but also contributes to lower operational costs in both industrial and consumer applications.

Another critical metric is the torque-to-weight ratio, which indicates how much weight the motor can handle relative to its size. A study conducted by the Society of Automotive Engineers (SAE) highlights that advanced DC gear motors now achieve torque-to-weight ratios exceeding 10:1, significantly enhancing their performance in compact applications. Furthermore, performance under varying load conditions, such as stall torque and no-load speed, must also be considered, as these factors directly impact the motor's effectiveness in real-world scenarios. By focusing on these metrics, manufacturers and engineers can make informed decisions that maximize the performance and efficiency of DC gear motors in their designs.

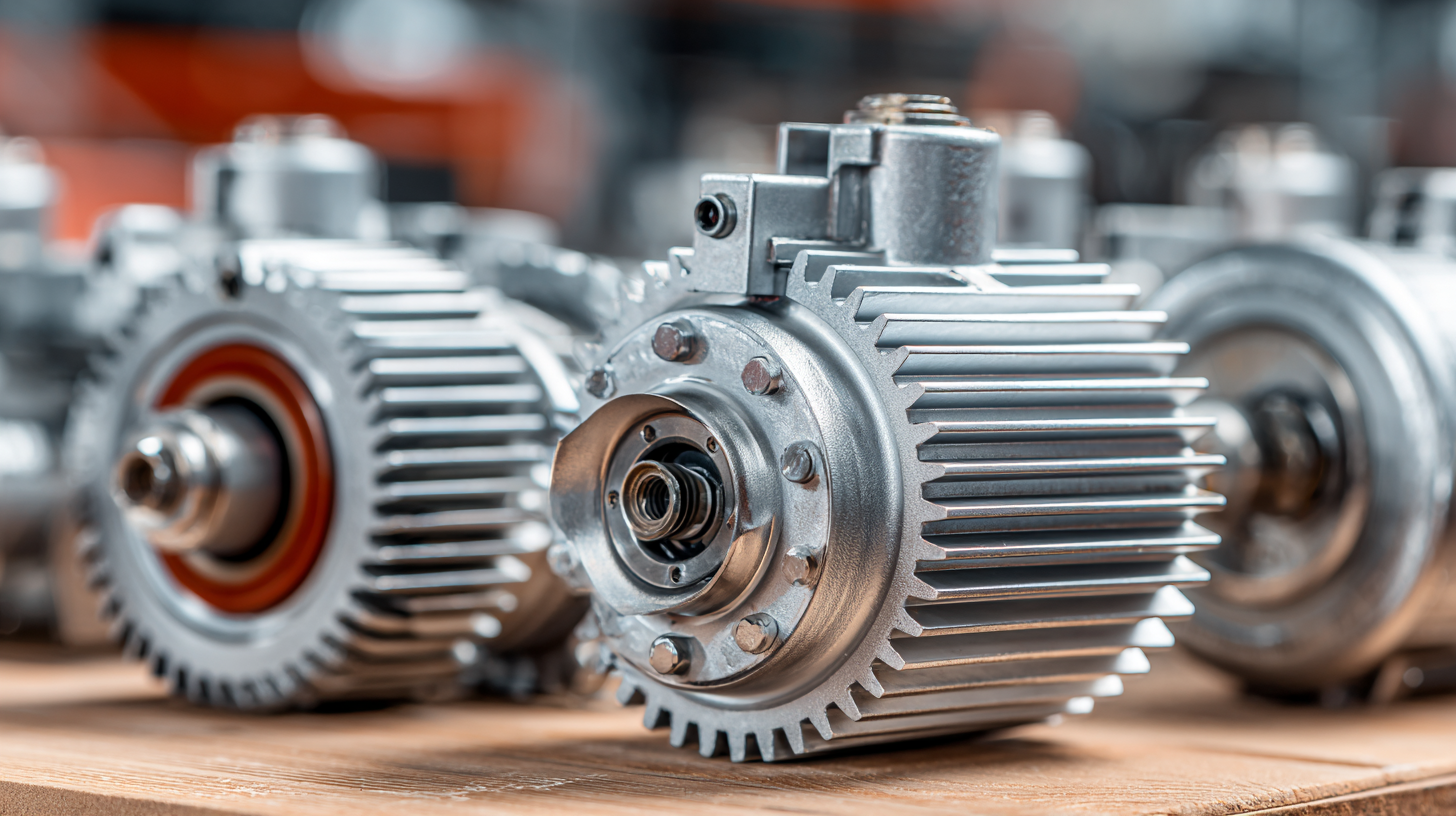

The increasing integration of DC gear motors in automation and robotics highlights their critical role in modern industry. As the demand for efficient and flexible automation solutions rises, DC gear motors have emerged as a key player due to their adaptability and efficiency. These motors are not only essential for traditional manufacturing processes but are also pivotal in the advancement of robotics, which requires precision and reliability. The global gear motor market is projected to reach USD 10.6 billion by 2035, reflecting a compound annual growth rate (CAGR) of 5.0% from 2025 to 2035. This growth underscores the expanding applications and innovations within the sector.

Tips for Choosing DC Gear Motors: When selecting a DC gear motor for your application, consider the power output as well as the voltage requirements. A clear understanding of your system's demands will help in optimizing performance. Additionally, think about the integration with existing systems; ensuring compatibility can significantly enhance operational efficiency.

Moreover, keep an eye on market trends. The brushless DC motor market, for example, is anticipated to grow significantly, reaching approximately USD 20.68 billion by 2030. Staying informed on developments in motor technologies can provide a competitive edge and more informed decisions for future automation projects.

This chart illustrates the increasing market demand for DC gear motors over a five-year period, highlighting their growing significance in automation and robotics industries.

As the demand for efficient and high-performance DC gear motors increases, the future of motor technology is poised for significant advancements. Emerging trends indicate that manufacturers are increasingly focusing on localized production and in-house powertrain development to enhance performance while reducing costs. This shift is likely to not only improve efficiency but also encourage innovation in DC gear motor design and application. The ongoing investment in localized production aligns with industry reports suggesting a projected growth in electric motor demand, especially in the USA, where advancements in energy efficiency are at the forefront.

Innovations in battery technology are becoming a crucial element in the push for longer-range, faster-charging electric vehicles. This evolution is reflected in various market analyses, which highlight a compound annual growth rate (CAGR) of 6.2% for the electric motor sector up to 2032, driven largely by advancements in DC gear motor technology. This synergy between motor technology and battery innovations underscores the critical role of DC gear motors in meeting the evolving demands of the automotive industry, particularly in the electric vehicle market, which is seeing unprecedented growth fueled by increased investments in R&D.

DC gear motors have become integral in a multitude of industries, showcasing their versatility and efficiency across various applications. In the automotive sector, for instance, they drive essential functions such as electronic steering and power window operations, enhancing performance and user experience. Similarly, in robotics, DC gear motors enable precise movements and control, underscoring their role in automation and innovative technology implementations.

The healthcare industry also harnesses the power of DC gear motors, particularly in devices that require reliable and consistent operation, such as surgical tools and medical imaging equipment. As industries continue to evolve, the demand for high-efficiency motors persists, reflecting a projected growth of the gear motor market, which is expected to reach USD 6.2 billion by 2024. This growth is fueled not only by automotive and healthcare applications but also by advancements in energy efficiency and automation across various sectors, showcasing the critical role DC gear motors play in driving performance and operational excellence.

Office: (281) 855-2218

Copyright © 2025 Telco Intercontinental Corp. All rights reserved. Privacy Policy | Legal Disclaimer

Telco®, TelcoMotion®, and TelcoGreen® are registered trademarks of Telco Intercontinental Corp.