Main Menu

In today's rapidly evolving technological landscape, DC gear motors have emerged as vital components in various applications ranging from robotics to automotive systems. Their unique features, such as high torque output and precise speed control, make them indispensable for global buyers in diverse industries. This blog will delve into the different types of DC gear motors available in the market, highlighting their distinct characteristics and suitability for specific applications. We will explore the nuances of selecting the right DC gear motor based on your project's requirements and provide valuable insights into how to integrate these motors effectively into your designs. Whether you are a seasoned engineer or a novice enthusiast, this comprehensive guide aims to equip you with the knowledge to navigate the world of DC gear motors confidently.

DC gear motors are essential components in a wide range of applications, from robotics to automotive systems. One of their unique characteristics is the ability to provide high torque at low speeds, making them ideal for tasks that require precision and control. This characteristic is crucial in applications such as conveyor systems, where slow and steady movement is necessary to transport goods efficiently.

Tips: When selecting a DC gear motor, consider the torque and speed requirements specific to your application. A motor with a high gear ratio can significantly enhance torque output, which is especially beneficial in scenarios requiring heavy lifting or precise movement.

Another unique feature of DC gear motors is their compact design, which allows them to be integrated into small spaces. This is particularly valuable in consumer electronics, where design considerations often necessitate smaller components without sacrificing performance.

Tips: Always evaluate the physical dimensions and mounting options of a DC gear motor to ensure that it fits well within your design requirements. Proper alignment and installation can lead to increased efficiency and lifespan of the motor in the long run.

When selecting DC gear motors, it's essential to focus on key technical specifications to ensure optimal performance for various applications. Factors such as torque, speed, voltage, and efficiency play a critical role in determining how well a motor will meet specific needs. For instance, a motor with higher torque is better suited for heavy-load applications, while a higher speed rating may be necessary for tasks requiring quick movement. Additionally, understanding the gear reduction ratio can help buyers select a motor that maximizes output efficiency, particularly in scenarios like robotics or automation.

New trends in electric motors further emphasize the importance of informed selection, especially in the evolving landscape of electric vehicle propulsion systems. As technology advances, the demand for motors that provide better energy efficiency and performance is rising. Buyers should also consider the compatibility of the motors with existing components and the ease of integration into their projects. By prioritizing these specifications, global buyers can ensure they choose DC gear motors that not only meet their application's requirements but also contribute to the growing trend of sustainable and efficient motor technology.

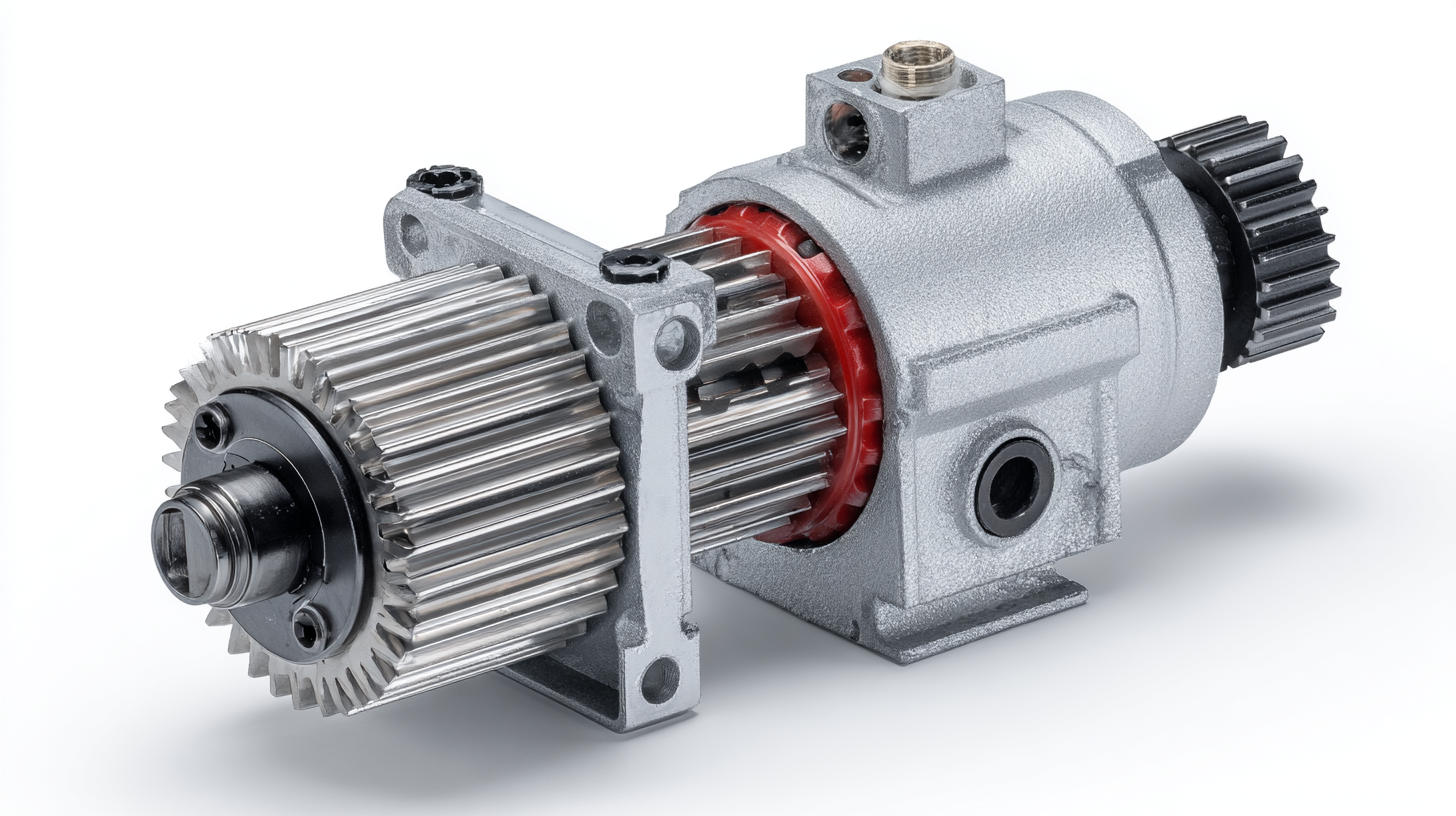

When selecting the right DC gear motor, understanding the comparative features of the various models available in the market is crucial for global buyers. Major brands like Maxon, Faulhaber, and Buehler offer gear motors with distinct characteristics. For instance, Maxon gear motors are renowned for their exceptional precision and compact design, making them ideal for applications requiring high torque in limited spaces. On the other hand, Faulhaber motors often excel in high efficiency and low noise, appealing to sectors where seamless operation is paramount.

Additionally, variations in gearing mechanisms play a significant role in performance. Some manufacturers utilize high-quality planetary gears, providing advantages in terms of reduced backlash and enhanced performance under load. In contrast, spur gears can often be more cost-effective while still offering good torque output. By analyzing these elements—like size, torque ratings, and efficiency—buyers can tailor their choices to specific applications, ensuring optimum performance in everything from robotics to automotive applications.

| Motor Type | Voltage (V) | Torque (Nm) | Speed (RPM) | Efficiency (%) | Application |

|---|---|---|---|---|---|

| Planetary Gear Motor | 12 | 1.5 | 180 | 85 | Robotics |

| Stepper Gear Motor | 24 | 2.0 | 300 | 80 | 3D Printing |

| Brushed DC Gear Motor | 6 | 0.5 | 100 | 75 | Consumer Electronics |

| Coreless DC Gear Motor | 9 | 0.8 | 150 | 90 | Medical Devices |

| DC Worm Gear Motor | 12 | 1.0 | 120 | 80 | Automated Systems |

DC gear motors have become integral in a plethora of industries, owing to their efficiency, compactness, and reliability. In the automotive sector, for instance, these motors are pivotal in powering electric windows, seat adjustments, and automatic door locks. According to a recent report by MarketWatch, the global automotive gear motor market is projected to grow at a CAGR of 4.5% from 2023 to 2030, underscoring the significance of these components in modern vehicles. As the trend towards electric vehicles accelerates, the demand for sophisticated DC gear motors will only intensify, driving innovation and competition among manufacturers.

Furthermore, in the robotics industry, DC gear motors facilitate precise movement and control required for robotic arms and automated assembly lines. A study by ResearchAndMarkets indicates that the global industrial robotics market is anticipated to reach $71.7 billion by 2028, with a significant portion of this growth attributed to advancements in motor technology. The adaptability of DC gear motors makes them suitable for various applications, including medical devices, packaging machinery, and consumer electronics, where they enhance operational efficiency and performance. With ongoing technological advancements, the versatility of DC gear motors positions them as essential components across diverse industrial applications.

When integrating DC gear motors into your projects, understanding their unique features is essential for maximizing performance and efficiency. Start by evaluating your project requirements, including load capacity, torque, and speed. Selecting the right motor involves matching these parameters with the specifications of the DC gear motor, ensuring that it can handle the demands of your application without overloading or underperforming.

Furthermore, it's crucial to consider the integration process itself. Proper alignment of the motor with the driven load can significantly reduce wear and tear, enhancing overall longevity. Employing suitable mounting techniques and vibration dampening methods will ensure stability and minimize noise. Don't forget to use appropriate power supplies to avoid voltage fluctuations that can affect motor performance. By following these guidelines, you can achieve a smoother workflow and enjoy the benefits of reliable and efficient operation of your DC gear motors in diverse applications.

Office: (281) 855-2218

Copyright © 2025 Telco Intercontinental Corp. All rights reserved. Privacy Policy | Legal Disclaimer

Telco®, TelcoMotion®, and TelcoGreen® are registered trademarks of Telco Intercontinental Corp.