Main Menu

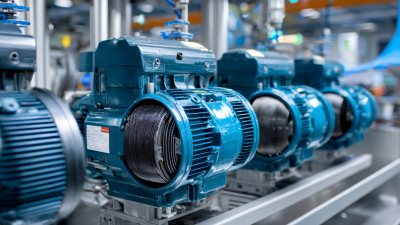

Electric motors are pivotal in transforming electrical energy into mechanical motion, with the global electric motor market expected to reach $168 billion by 2025, according to a report by Research and Markets. This remarkable growth reflects the rising demand for energy-efficient solutions across various industries, including automotive, manufacturing, and renewable energy sectors. With over 300 million electric motors currently in use worldwide, they not only power everyday appliances, but also drive industrial automation and electric vehicles, significantly contributing to reducing carbon emissions. The advancements in electric motor design, including the integration of smart technologies, enhance their performance and efficiency, making them a cornerstone of modern engineering. Understanding the science behind electric motors is crucial as they continue to play a transformative role in our energy landscape, highlighting their significance in sustainable development and technological innovation.

Electromagnetic forces are at the core of how electric motors function, harnessing the principles of electromagnetism to transform electrical energy into mechanical motion. The foundational aspect of this process is Faraday's Law of Electromagnetic Induction, which illustrates how changes in magnetic fields can induce electric currents. This relationship underpins the operation of various types of motors, including recent advancements in electrostatic motors, which have now expanded beyond micro-scale applications to larger, macro-scale systems. Such developments testify to the versatility of electromagnetic principles in modern engineering.

Innovations involving electromagnetic design extend into various fields, including transportation. The application of magnetic levitation technology for trains has revolutionized public transport, illustrating the practical benefits of electromagnetic suspension systems. Additionally, hybrid excitation motors demonstrate an advanced manipulation of electromagnetic forces, allowing for enhanced efficiency and performance in industrial settings. As these technologies evolve, they highlight the critical role that electromagnetic principles play in driving forward the capabilities and efficiency of electric motors across multiple domains.

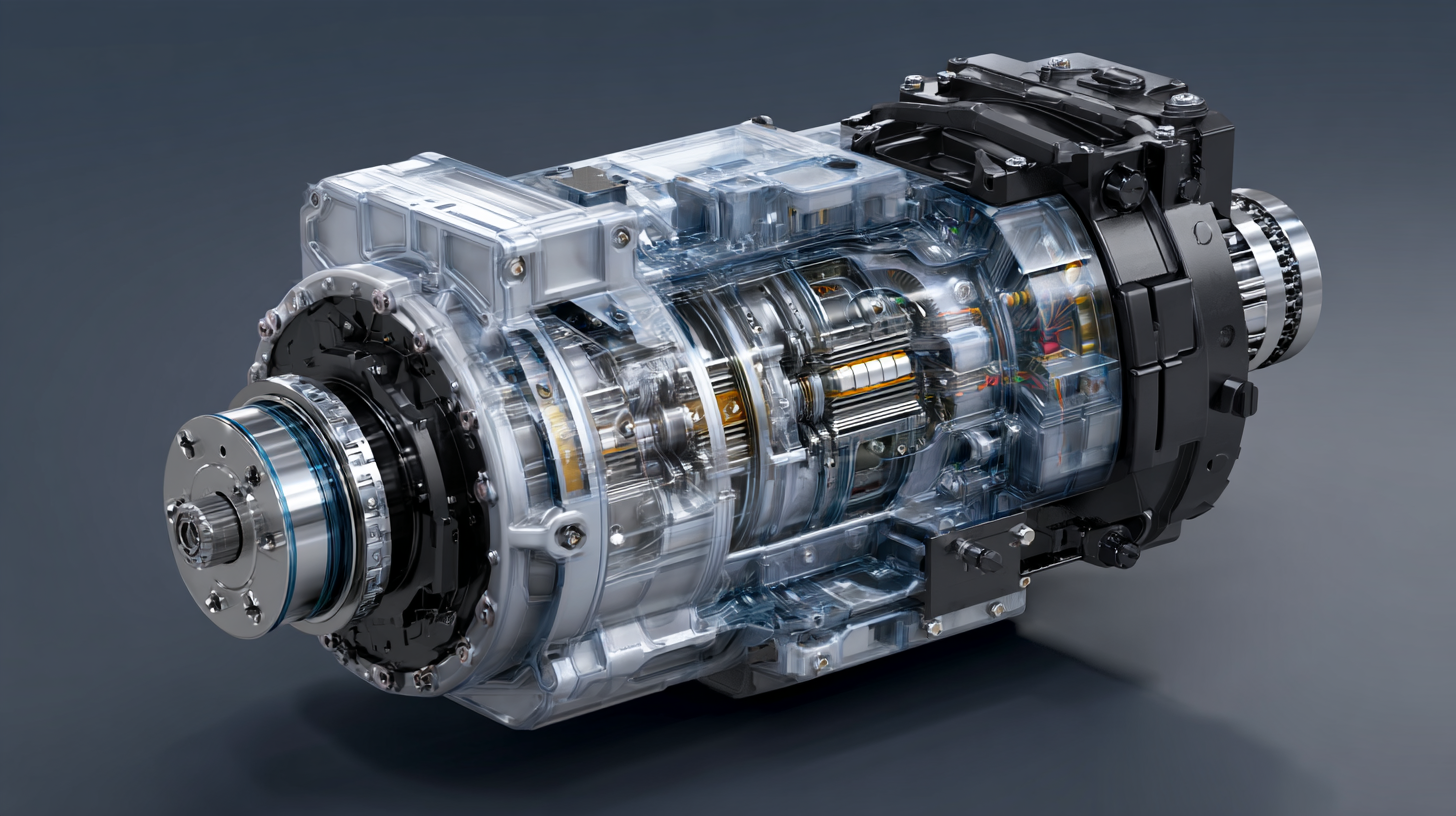

Electric motors play a pivotal role in transforming electrical energy into mechanical energy, serving as the heart of various applications, particularly in electric vehicles (EVs). These motors operate by converting electricity into movement, which propels vehicles forward efficiently. Unlike traditional pneumatic systems, electric motors showcase superior energy efficiency, converting a higher percentage of electrical input into tangible mechanical work. Recent innovations, like the "Hairpin" wiring technology, further enhance this efficiency, allowing modern motors to achieve higher performance with less energy consumption.

Moreover, advancements in electric motor design continue to dispel long-held myths about efficiency losses in electric propulsion systems. State-of-the-art electric motors exhibit minimal energy loss, effectively optimizing the energy conversion process. As the global demand for cleaner energy solutions rises, the motor market is projected to expand significantly, reflecting a growing awareness of the advantages offered by electric motors in reducing energy consumption while supporting a sustainable future. This progress underscores the importance of understanding electric motors' functionality in converting electrical energy into mechanical energy, facilitating a transformative shift toward energy-efficient technologies.

This chart illustrates the basic energy conversion process in electric motors, representing the input electrical energy, the output mechanical energy, and the efficiency of conversion. In this example, 100 kWh of electrical energy results in 85 kWh of mechanical energy output, showcasing an efficiency of 85%.

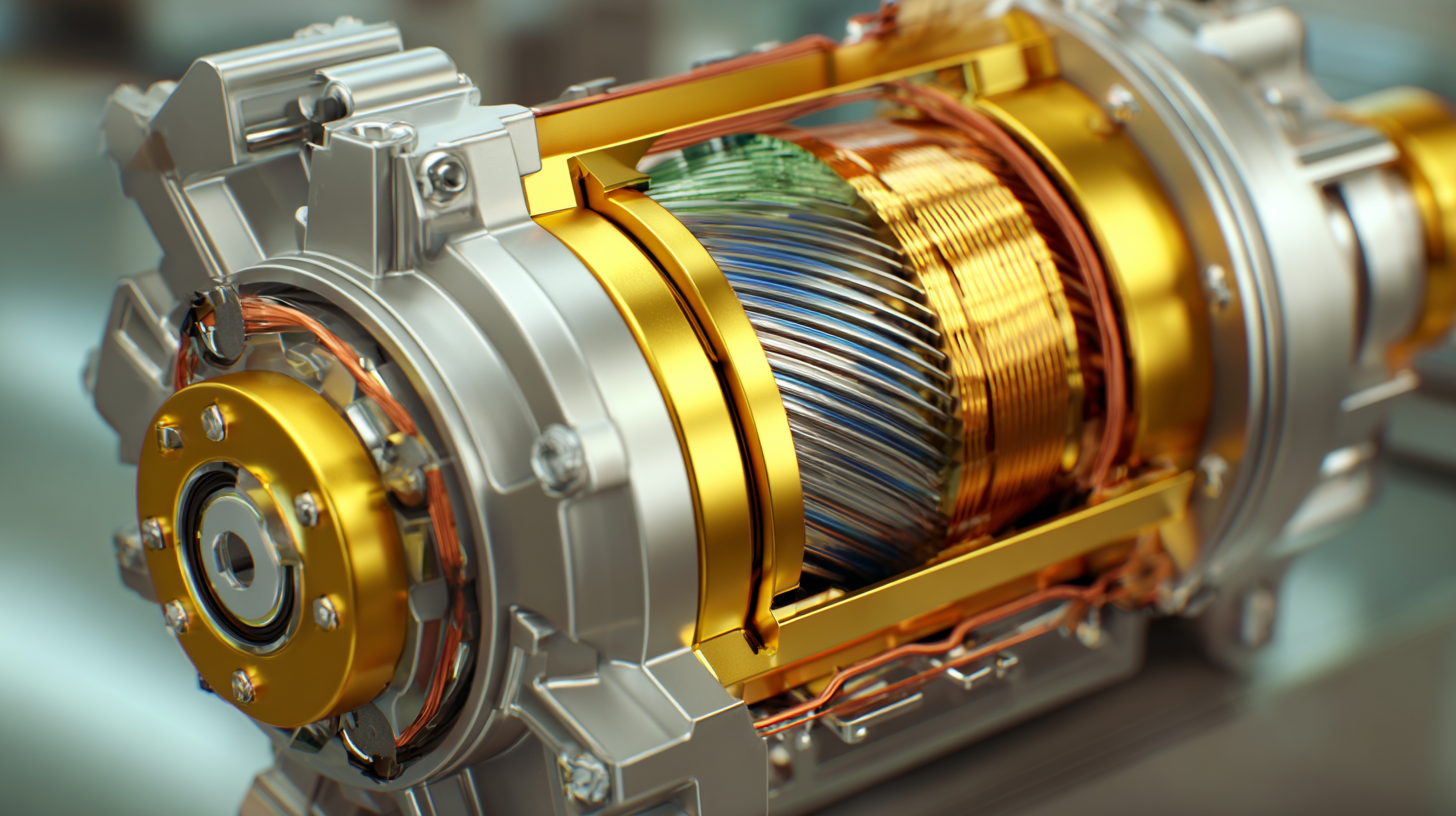

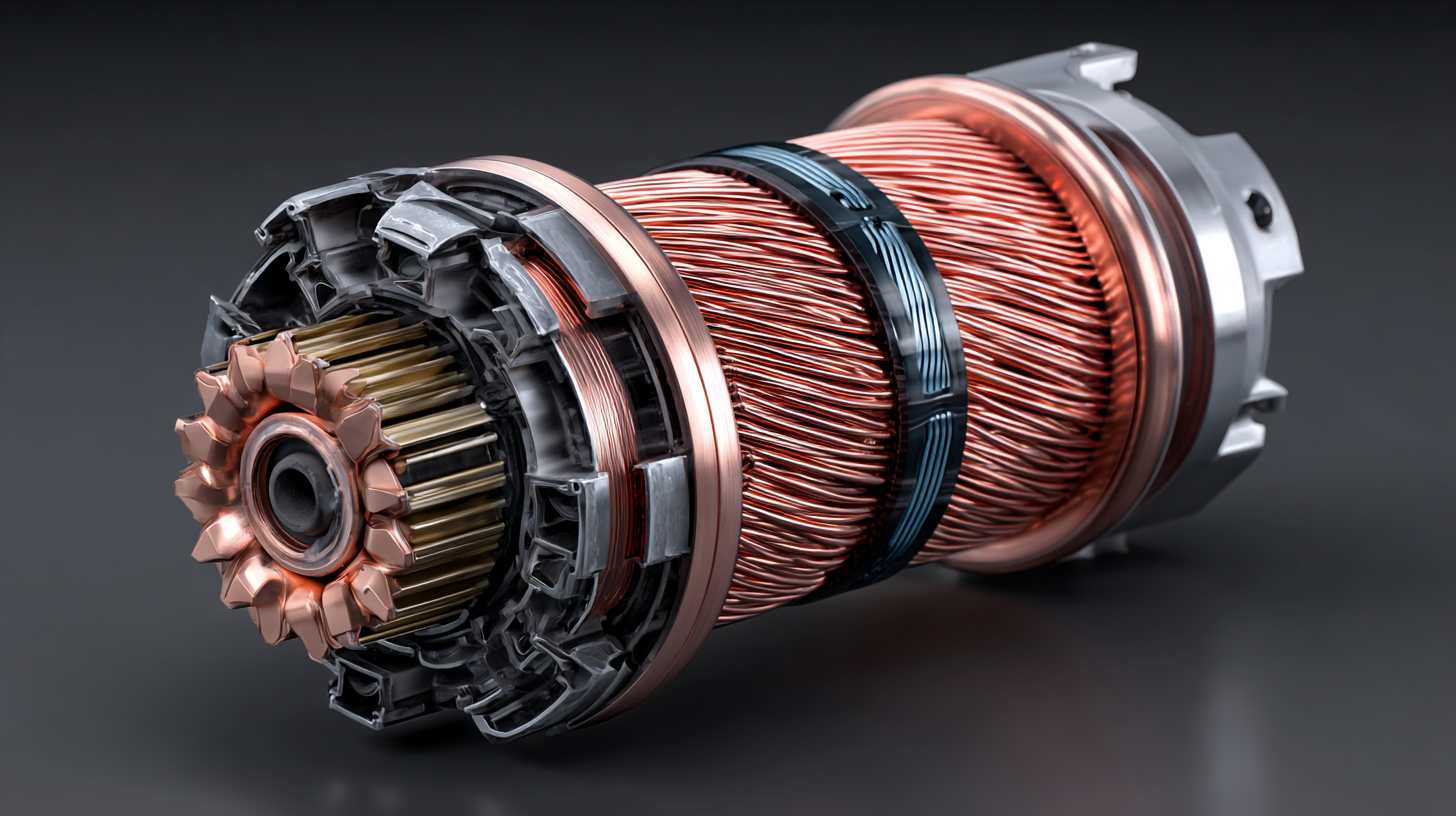

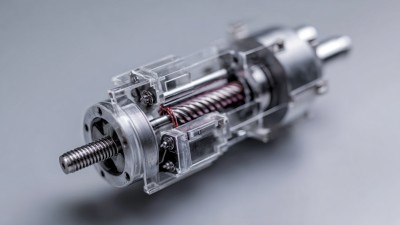

Electric motors play a crucial role in converting electrical energy into mechanical motion, and their anatomy comprises several key components. The primary parts include the stator, rotor, commutator, and brushes. The stator, often the stationary part, generates a magnetic field that interacts with the rotor, the rotating element of the motor. This interaction produces rotational motion, allowing electric energy to be transformed efficiently into kinetic energy.

Electric motors play a crucial role in converting electrical energy into mechanical motion, and their anatomy comprises several key components. The primary parts include the stator, rotor, commutator, and brushes. The stator, often the stationary part, generates a magnetic field that interacts with the rotor, the rotating element of the motor. This interaction produces rotational motion, allowing electric energy to be transformed efficiently into kinetic energy.

Understanding these components can enhance the engineering and design of electric motors. For instance, optimizing the materials used in the rotor and stator, such as high-grade magnets and conductive metals, can significantly improve efficiency. Additionally, proper maintenance of the brushes and commutator ensures consistent performance and longevity of the motor.

Tips for anyone interested in electric motors include focusing on the cooling systems, which are essential for preventing overheating during operation. Also, consider investing in quality components since they can greatly influence the overall performance and reliability of the motor in various applications. By grasping the key elements of electric motors, one can appreciate their efficiency in transforming energy into motion while also improving their performance.

Electric motors have become indispensable in various industries, particularly in the realm of automation and robotics. As of 2023, the industrial automation sector accounts for approximately 70% of gear applications, highlighting the critical role of electric motors in conveyor systems and manufacturing processes. The global three-phase AC motor market, valued at around $17.3 billion in 2024, is projected to reach $18.7 billion by 2033, reflecting a compound annual growth rate (CAGR) of 0.9%. This growth is driven by advancements in motor design and efficiency improvements that are focused on reducing energy loss.

As the demand for sustainable solutions rises, sectors like electric farming tractors are also seeing significant growth. The electric farming tractor market, which encompasses various types of tractors and battery systems, is positioned for considerable expansion, with the market size projected to grow impressively in the coming years. Innovations in motor technology and materials not only enhance performance but also improve energy efficiency across the board.

Tips: When selecting an electric motor for your application, consider factors such as efficiency ratings and the specific requirements of your operational environment. Investing in advanced motors can lead to significant long-term savings and enhanced performance. Always stay updated on market trends to ensure you’re utilizing the most efficient technologies available.

Electric motors are pivotal in various applications, ranging from household appliances to industrial machinery. The demand for electric motors is directly influenced by the growing need for energy efficiency and automation in numerous sectors. As industries strive to optimize performance and minimize operational costs, electric motors emerge as a critical component. Their versatility allows for implementation in a myriad of applications, including automotive, aerospace, and construction, further underscoring their importance in modern technology.

The market for electric motors, particularly within the context of industrial fasteners, has shown significant growth potential. Forecasts indicate an expansion driven by advancements in materials such as metals and plastics, which are essential for enhancing motor efficiency and durability. Specific product segments, including external and internal threads and aerospace-grade components, are expected to see increased demand. Additionally, the rise of high-speed motors and low-voltage electric vehicles reflects a broader trend towards sustainable and high-performance engineering, positioning electric motors at the forefront of industrial innovation.

Office: (281) 855-2218

Copyright © 2025 Telco Intercontinental Corp. All rights reserved. Privacy Policy | Legal Disclaimer

Telco®, TelcoMotion®, and TelcoGreen® are registered trademarks of Telco Intercontinental Corp.