Main Menu

In today's rapidly advancing technological landscape, the selection of the right precision DC motor has become paramount for various applications, ranging from robotics to medical devices. According to a recent market report by Research and Markets, the global precision DC motor market is projected to reach $1.2 billion by 2027, with a compound annual growth rate (CAGR) of 6.5% over the forecast period. This growth is driven by increasing demands for high-performance motors that offer exceptional reliability and efficiency. As industries strive for automation and precision in their operations, the need for well-engineered precision DC motors that match specific application requirements becomes crucial. Understanding key factors such as torque, speed, and size not only aids in optimizing performance but also significantly enhances the longevity and overall effectiveness of the application. This guide aims to equip engineers and decision-makers with insights into selecting the ideal precision DC motor tailored to their unique operational needs.

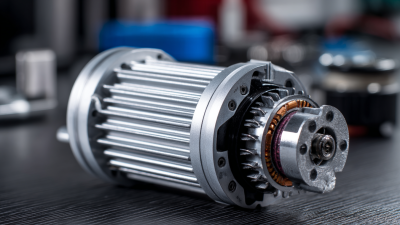

When selecting the right precision DC motor for your application, understanding your specific requirements is crucial. Different applications demand varying levels of precision, torque, and speed control. According to a report by Grand View Research, the global DC motor market was valued at $23.21 billion in 2022 and is projected to grow at a CAGR of 6.9% from 2023 to 2030. This growth highlights the increasing reliance on precision DC motors in industries ranging from robotics to medical devices, where performance specifications are paramount.

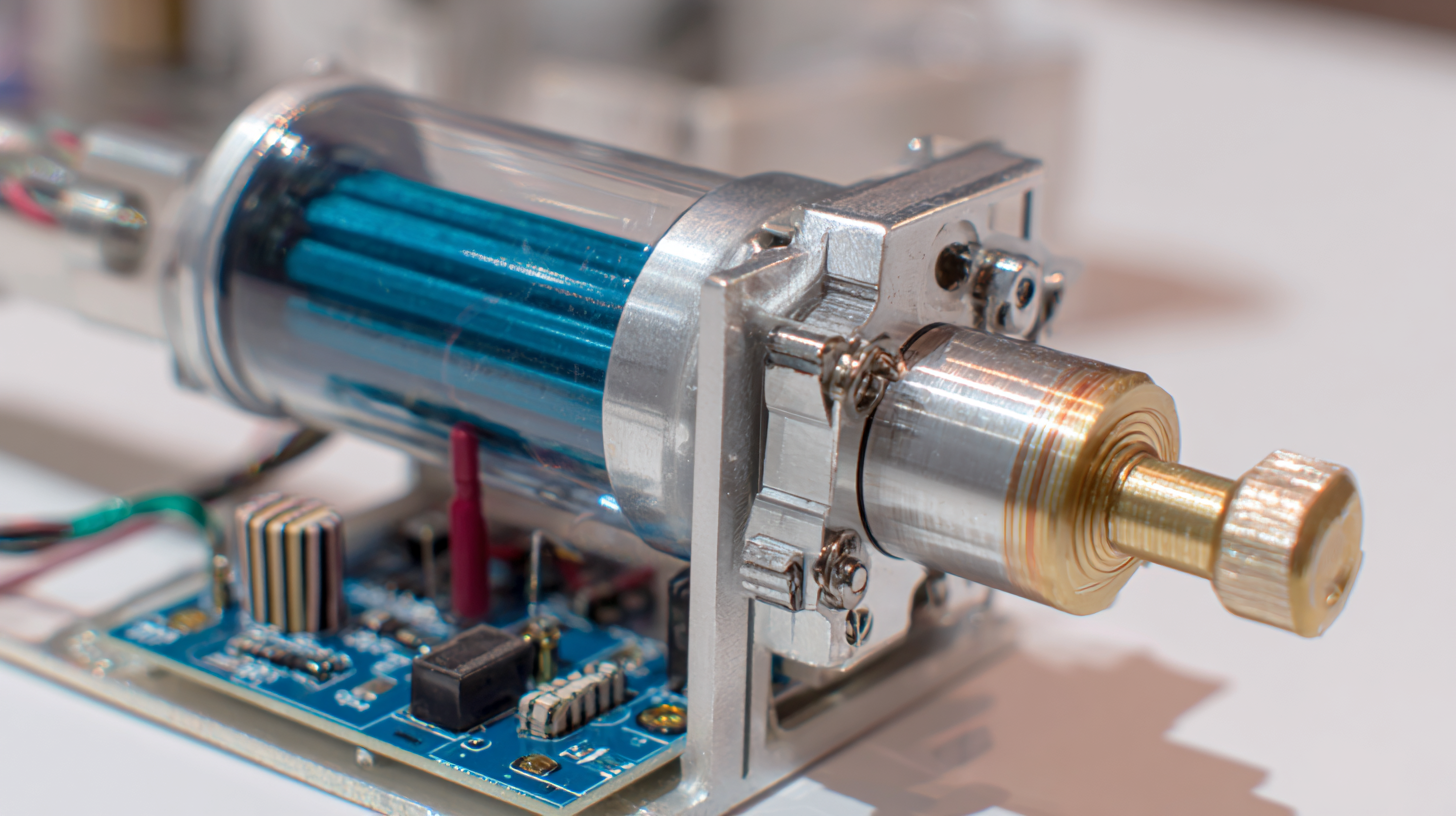

Before making a decision, consider the load characteristics and operational environment of your application. For instance, low-torque applications may benefit from **brushed DC motors** due to their simplicity and cost-effectiveness. In contrast, applications requiring high efficiency and precise control might be better suited for brushless DC motors, which offer enhanced reliability and longer lifespans. According to a study conducted by Research and Markets, brushless motors are anticipated to capture over 40% of the market share by 2025, underscoring their growing importance in advanced applications. Understanding these nuances can guide manufacturers in choosing the most appropriate motor for their specific needs.

When selecting a precision DC motor for your application, several key specifications play a crucial role in ensuring optimal performance. Firstly, torque output is essential; it determines the motor's ability to perform specific tasks. According to a report by the International Society of Automation, the required torque often varies depending on the load, with precision applications typically necessitating torque values in the range of 0.1 to 5 Nm. Understanding the torque requirements of your application can help in choosing a motor that delivers adequate power without unnecessary over-specification.

Another critical specification is the speed range and control capabilities. Precision applications may require a motor that maintains consistent speed while varying load conditions. According to the *2022 Precision Motor Systems Market Report*, motors with a good speed control mechanism can maintain an accuracy of ±1% RPM under variable loads, making them suitable for applications in robotics and automation. Furthermore, the size and weight of the motor should also be evaluated, especially in applications where space is constrained. Compact motors, while maintaining power efficiency, often provide a better fit for delicate mechanisms where precision is paramount.

| Specification | Description | Example Values |

|---|---|---|

| Voltage Rating | Operating voltage range for optimal performance. | 12V, 24V, 48V |

| Torque | The rotational force delivered by the motor. | 0.5 Nm, 1 Nm, 2 Nm |

| Speed | The rate of rotation, usually measured in RPM. | 100 RPM, 300 RPM, 600 RPM |

| Form Factor | Physical size and shape of the motor. | NEMA 17, NEMA 23 |

| Efficiency | Ratio of output power to input power. | 70%, 85%, 90% |

| Lifetime | Estimated operational hours before failure. | 5000 hours, 10000 hours |

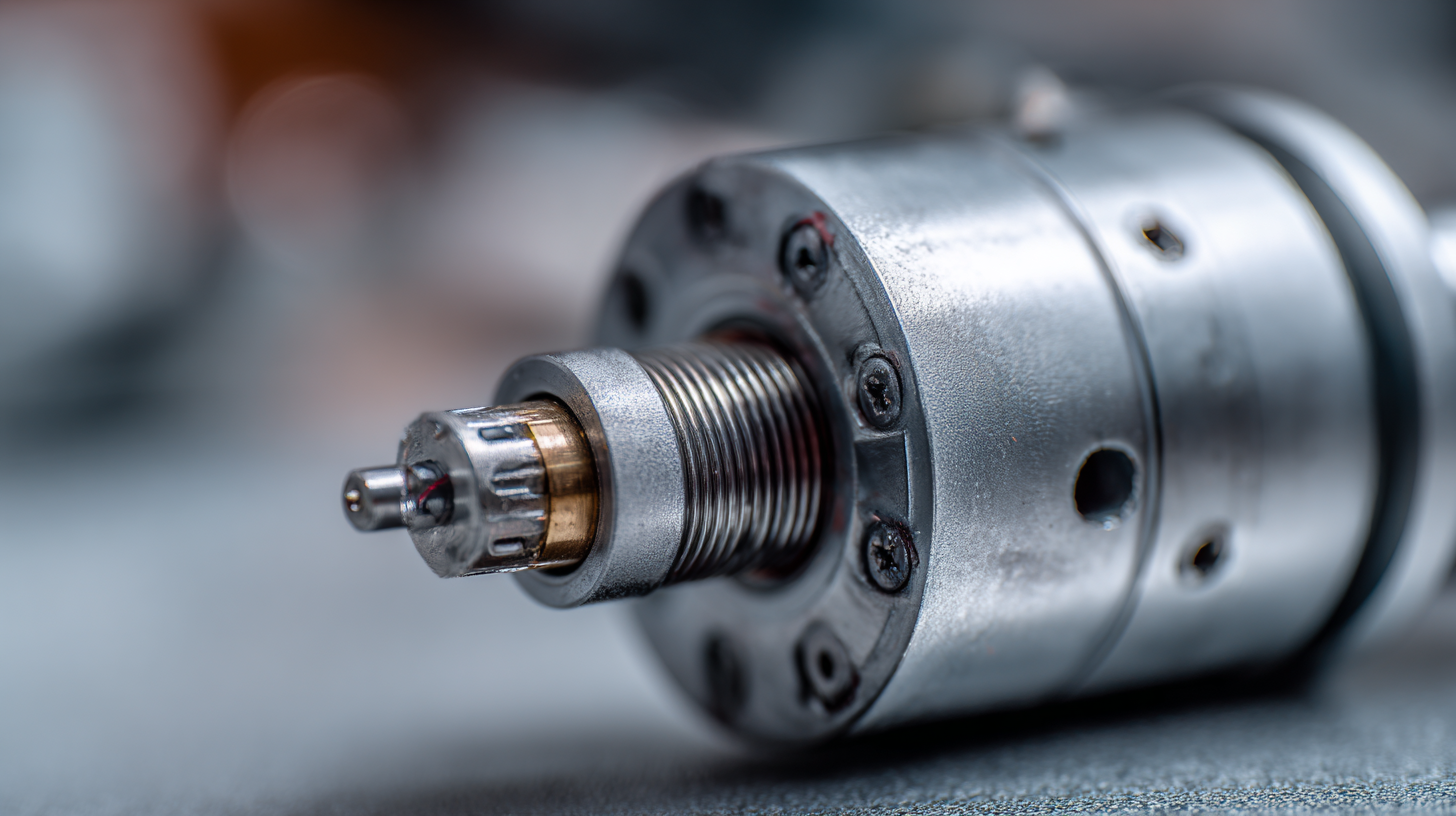

When selecting a precision DC motor for your application, evaluating the power and torque needs is crucial for achieving optimal performance. The first step is to determine the required power output, which is influenced by the nature of the task, load conditions, and desired speed. Consider the maximum load the motor will encounter and how frequently it will operate at full capacity. By calculating the power requirements, you can narrow down your choices to motors that can provide the necessary wattage without overloading.

Torque is another vital factor to consider. It reflects the motor's ability to perform work and is particularly significant in applications requiring acceleration or overcoming resistance. Analyze the torque curve of potential motors to ensure they can handle peak torque demands without faltering. For applications with variable loads, choosing a motor with a broad torque range ensures consistent performance. By carefully assessing both power and torque, you set the foundation for selecting a precision DC motor that aligns with your specific application needs.

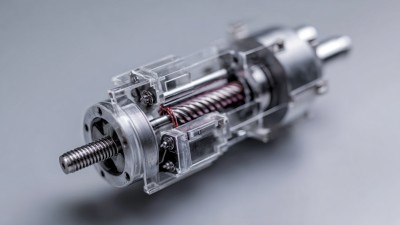

When selecting a precision DC motor, one of the most critical considerations is the control mechanism utilized to ensure both precision and stability. The efficiency of these motors can be significantly influenced by their control systems, such as Pulse Width Modulation (PWM) and closed-loop feedback systems. According to a report from the International Electrotechnical Commission, motors with optimized control mechanisms can enhance performance by up to 30%, especially in applications requiring precise positioning and speed control.

Tip: When assessing control mechanisms, ensure that the selected system is compatible with your application’s response time and accuracy requirements. For instance, a system that incorporates PID (Proportional-Integral-Derivative) controllers can offer improved stability and responsiveness under varying load conditions.

Additionally, the type of feedback sensor used—whether encoders or resolvers—can play a pivotal role in maintaining the motor’s performance. Industry data indicates that systems using high-resolution encoders can achieve position accuracies of ±1 arc minute or better. Selecting a control mechanism that leverages advanced sensors will not only ensure precision but also enhance the overall reliability of the motor in demanding environments.

Tip: Consider future scaling when selecting your motor's control mechanisms, as the ability to integrate additional sensors or adapt to different control algorithms can extend the lifespan and effectiveness of your application.

When selecting a precision DC motor, budget considerations play a crucial role in the decision-making process. It's essential to determine a clear budget range before beginning the sourcing process. According to industry reports, effective supply chain management can lead to cost savings of up to 20% in motor procurement. Evaluating the lifetime cost of ownership, which includes maintenance and operational efficiency, can further guide your budget allocation.

Additionally, sourcing reliable motor suppliers is paramount to ensuring product quality and longevity. Conduct thorough research to identify suppliers with proven track records in meeting safety and performance standards. Tips for verifying supplier reliability include checking for relevant certifications and reading customer reviews to gauge the experiences of other clients. Partnering with suppliers who prioritize transparency in their sourcing processes can also mitigate potential supply chain disruptions.

In an evolving market influenced by geopolitical factors, such as recent AI security memos and changes in procurement protocols, staying informed about market conditions and supplier stability can significantly impact your project's success. Balancing budget constraints with the need for high-quality components will ultimately determine the effectiveness of your precision DC motor solution.

Office: (281) 855-2218

Copyright © 2025 Telco Intercontinental Corp. All rights reserved. Privacy Policy | Legal Disclaimer

Telco®, TelcoMotion®, and TelcoGreen® are registered trademarks of Telco Intercontinental Corp.