Main Menu

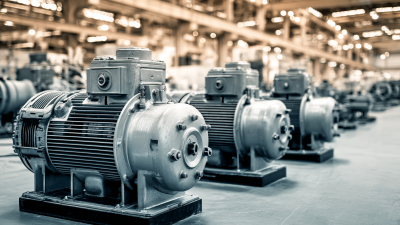

In the rapidly evolving landscape of modern manufacturing, the role of the industrial AC motor has become increasingly pivotal. As industries strive for enhanced efficiency, reliability, and automation, understanding the intricacies of these motors is essential for optimizing production processes.

Industrial AC motors, known for their durability and performance, drive various machinery and equipment, from conveyor systems to machining tools. This guide aims to delve into the fundamental aspects of industrial AC motors, exploring their design features, operational advantages, and contributions to automation and sustainability in manufacturing.

By gaining insights into the selection, implementation, and maintenance of these motors, manufacturers can not only improve operational efficiency but also adapt to the demands of an ever-competitive market. Join us on this journey to uncover the significance of industrial AC motors in shaping the future of manufacturing processes.

Industrial AC motors, known for their durability and performance, drive various machinery and equipment, from conveyor systems to machining tools. This guide aims to delve into the fundamental aspects of industrial AC motors, exploring their design features, operational advantages, and contributions to automation and sustainability in manufacturing.

By gaining insights into the selection, implementation, and maintenance of these motors, manufacturers can not only improve operational efficiency but also adapt to the demands of an ever-competitive market. Join us on this journey to uncover the significance of industrial AC motors in shaping the future of manufacturing processes.

The evolution of industrial AC motors has been a remarkable journey marked by significant technological advancements that have transformed manufacturing processes. Initially, AC motors were primarily characterized by their simple design and moderate efficiency. However, over the decades, innovations such as the introduction of variable frequency drives (VFDs) have revolutionized their operation, allowing for precise speed control and energy efficiency. These advancements enable manufacturers to optimize their processes, reduce energy consumption, and enhance productivity.

Moreover, the integration of smart technologies has further elevated the capabilities of industrial AC motors. With the advent of the Internet of Things (IoT), modern AC motors can now communicate real-time data regarding performance, maintenance needs, and energy usage. This connectivity not only allows for predictive maintenance but also facilitates better integration within automated manufacturing systems. As a result, manufacturers can achieve greater reliability and efficiency, transforming traditional practices into agile, data-driven operations that meet the demands of today’s fast-paced industrial landscape.

| Technological Advancement | Description | Impact on Manufacturing | Year Introduced |

|---|---|---|---|

| Variable Frequency Drives (VFDs) | Allows for precise control of motor speed and torque. | Improves energy efficiency and process control. | 1980s |

| High-efficiency Motors | Motors designed to reduce energy consumption while maintaining performance. | Decreases operational costs and environmental impact. | 2000s |

| Integrated Motor Drives | Combines motor and drive into a single unit for ease of installation and maintenance. | Reduces space, improves reliability and setup efficiency. | 2010s |

| Smart Motor Technologies | Utilizes IoT for monitoring and control of motor operation. | Enhances predictive maintenance and operational efficiency. | 2020s |

| Permanent Magnet Motors | Uses permanent magnets to create a strong magnetic field, improving efficiency. | Increases power density and lowers energy usage. | 2000s |

In the modern manufacturing landscape, energy efficiency is paramount, and industrial AC motors play a crucial role in optimizing energy consumption. According to the U.S. Department of Energy (DOE), electric motors account for approximately 65% of the total industrial electricity consumption. By implementing energy-efficient AC motors, manufacturers can significantly reduce operational costs. For instance, using high-efficiency motors (NEMA Premium rated) can result in energy savings of up to 6% compared to standard efficiency motors, translating to substantial financial savings over time.

Moreover, advancements in motor technology, such as variable frequency drives (VFDs), further enhance efficiency by allowing motors to operate at optimal speeds based on demand. A study by the Electric Power Research Institute (EPRI) revealed that integrating VFDs with AC motors can lead to energy savings of up to 50% in certain applications. This dynamic capability not only optimizes performance but also reduces the overall carbon footprint of manufacturing operations, aligning with sustainability goals that are increasingly important in today’s industry. As manufacturers strive for improved efficiency metrics, the integration of advanced AC motor technology is essential for enhancing productivity and reducing energy consumption.

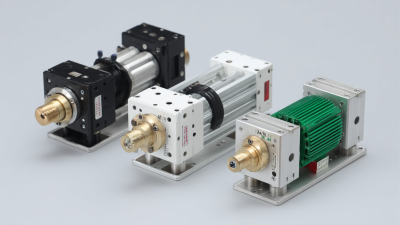

In modern manufacturing processes, industrial AC motors play a crucial role in driving various applications, particularly in robotic arms and conveyor systems. These motors are known for their reliability and efficiency, making them ideal for assembly line operations where precision and speed are paramount. According to industry reports, the servo motors and drives market was valued at approximately $13.9 billion in 2024 and is projected to grow to $20 billion by 2032, highlighting the increasing reliance on these technologies in automation.

Furthermore, the use of industrial AC motors in belt conveyor systems exemplifies their versatility. A typical conveyor setup includes components such as a temperature sensor, electric motor, coupling, and gearbox, which work synergistically to ensure seamless material handling. As indicated by recent studies, implementing advanced motor control systems can enhance performance and energy efficiency, which is essential for meeting production demands while minimizing operational costs. This shift towards incorporating smart motor solutions underscores the critical function of industrial AC motors in shaping the future of manufacturing.

In modern manufacturing processes, understanding the differences between AC motors and DC motors is crucial for achieving optimal efficiency and productivity. AC motors are generally favored in production lines due to their robustness, lower maintenance requirements, and efficiency over long operational periods. They typically offer higher power-to-weight ratios, making them ideal for driving heavy machinery and equipment in large-scale manufacturing settings.

On the other hand, DC motors provide precise speed control and higher starting torque, which can be advantageous in applications requiring fine-tuned movements, like robotic assembly lines. However, they often require more maintenance and may not be as durable as their AC counterparts in extensive industrial applications.

Tips for Choosing the Right Motor:

As smart technology continues to make significant strides, industrial AC motors are undergoing pivotal transformations in performance and efficiency. The integration of IoT (Internet of Things) devices with AC motors allows for real-time monitoring and predictive maintenance, reducing downtime by an estimated 30% according to McKinsey & Company. These advances not only enhance operational efficiency but also lead to significant cost savings and improvements in the lifespan of motor systems.

One of the most promising trends is the application of machine learning algorithms to analyze data collected from these motors. By predicting failures and optimizing operational parameters, manufacturers can improve their production processes and reduce energy consumption. A recent report by Gartner highlights that companies that adopt smart motor technologies can expect to see a decrease in energy costs by up to 15% annually.

Tips for manufacturers looking to leverage smart technology: First, invest in retrofitting existing equipment with smart sensors to gather insightful data without the need for complete system overhauls. Secondly, collaborate with technology providers to ensure seamless integration of IoT devices with existing networks, maximizing the benefits of smart technology in enhancing motor performance. By staying ahead of these trends, manufacturers can ensure their processes remain competitive in an ever-evolving market.

Office: (281) 855-2218

Copyright © 2025 Telco Intercontinental Corp. All rights reserved. Privacy Policy | Legal Disclaimer

Telco®, TelcoMotion®, and TelcoGreen® are registered trademarks of Telco Intercontinental Corp.