Main Menu

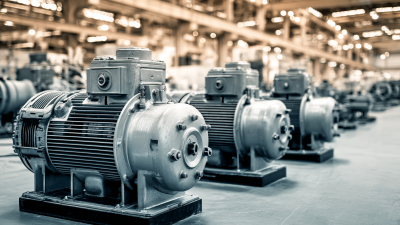

In today's industrial landscape, the demand for energy efficiency is more pressing than ever, prompting businesses to seek innovative solutions to optimize their operations. According to the International Energy Agency (IEA), electric motors account for approximately 70% of industrial electricity consumption, underscoring the pivotal role of motor power motors in enhancing energy performance. Furthermore, the U.S. Department of Energy estimates that improving the efficiency of motor systems could save over $5 billion in energy costs annually. With advancements in technology, modern motor power motors are designed not only to reduce energy consumption but also to increase productivity and reliability. This article will explore the critical importance of motor power motors in driving energy efficiency across various industries, offering actionable tips on how businesses can implement these systems to achieve significant cost savings and environmental benefits.

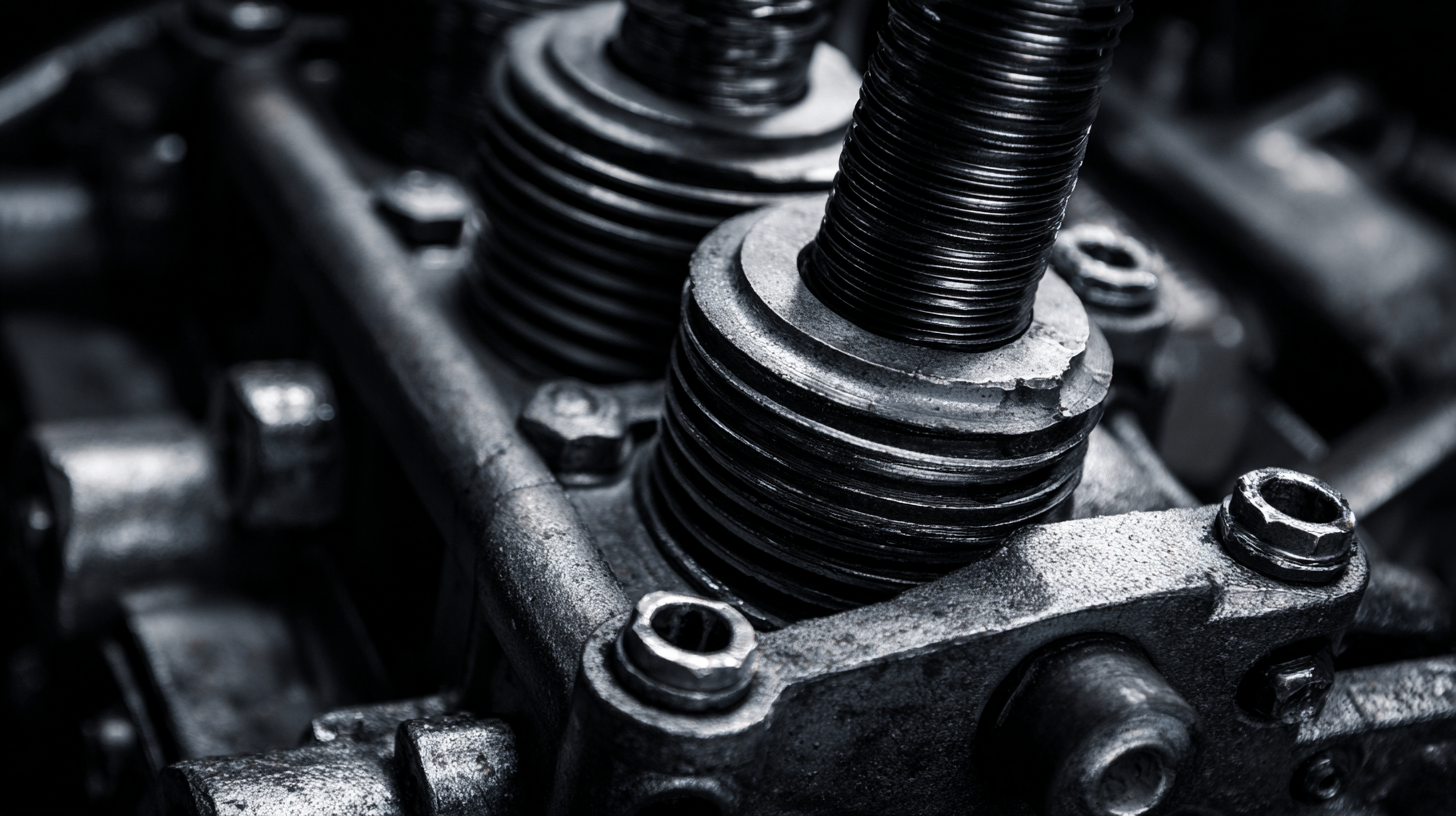

The role of motor power in enhancing energy efficiency is crucial in modern industries, where the demand for sustainable practices is on the rise. Motors are integral components in various applications, driving everything from conveyor systems to manufacturing equipment. By optimizing motor power, industries can significantly reduce energy consumption, thereby lowering operational costs and minimizing their carbon footprint.

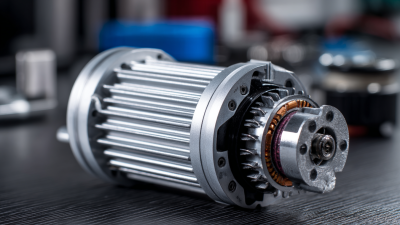

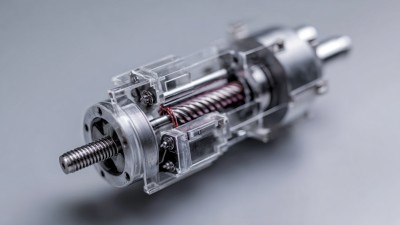

Advanced motor technologies, such as variable frequency drives and high-efficiency motors, have emerged as effective solutions for improving energy efficiency. These innovations allow for precise control of motor speed and torque, enabling systems to operate only as needed rather than at constant, less efficient levels. As a result, industries not only benefit from reduced energy costs but also contribute to broader environmental goals. Adopting enhanced motor power strategies is a key step toward achieving greater energy efficiency and sustainability in today's industrial landscape.

| Industry | Power Rating (kW) | Energy Efficiency (%) | Annual Energy Consumption (MWh) | Savings Potential (%) |

|---|---|---|---|---|

| Manufacturing | 50 | 90 | 250 | 15 |

| Water Treatment | 75 | 85 | 500 | 18 |

| Food Processing | 60 | 92 | 300 | 12 |

| HVAC Systems | 30 | 95 | 200 | 20 |

| Textile Industry | 40 | 88 | 350 | 10 |

In the realm of modern industries, the pursuit of energy efficiency has become paramount. One of the key technologies driving innovations in motor power is the advancement in electric vehicle (EV) battery systems. The rapid uptake of electric vehicles is not only revolutionizing transportation but also pushing the boundaries of battery technology, improving energy density, safety, and recycling processes.

Conferences and forums are now dedicated to addressing the crucial challenges in this sector, fostering collaboration among industry leaders to overcome technological bottlenecks.

Additionally, the synergy between electric motors and innovative energy solutions is fostering a competitive edge within the automotive landscape. As new power systems emerge, they are designed to optimize performance while significantly reducing carbon footprints. This trend is reflected in initiatives aimed at enhancing the recycling infrastructure for lithium-ion batteries, which is critical for sustainable industrial practices.

Tips: Embrace new technologies and robust recycling strategies to stay ahead in energy efficiency. Collaborate with industry peers to share knowledge and innovate effectively. Prioritize sustainable practices to enhance competitiveness in the evolving market landscape.

The importance of energy-efficient motors in modern industries cannot be overstated, particularly when considering their significant impact on operational costs. The global energy-efficient motor market is projected to expand from $54.60 billion in 2025 to $80.86 billion by 2032, with a compound annual growth rate (CAGR) of 5.77%. This growth highlights the increasing awareness among industries about the cost savings associated with transitioning to higher efficiency motors. For instance, the adoption of energy-efficient motor-driven systems could potentially save Europe up to 202 billion kWh in electricity consumption, translating into a staggering reduction of €10 billion in costs.

Furthermore, optimizing motor efficiency through advanced technologies, such as variable frequency drives, can dramatically enhance energy savings while concurrently lowering operating costs. These advancements are essential not only for cost minimization but also for reducing carbon footprints and supporting sustainability initiatives. As industries face rising energy costs and environmental pressures, investing in energy-efficient motors becomes a strategic move towards achieving stronger operational performance and economic benefits in the long run.

The comparative analysis of traditional and modern motor power systems reveals significant advancements that enhance energy efficiency across various industrial applications. Traditional motors, while reliable, often fall short in optimizing power usage, leading to higher operational costs. In contrast, modern motor power systems, equipped with advanced technologies such as variable frequency drives and smart sensors, enable precise control of energy consumption. This transition not only reduces waste but also facilitates better integration within automated environments, where about 70% of gear applications are now utilized.

The comparative analysis of traditional and modern motor power systems reveals significant advancements that enhance energy efficiency across various industrial applications. Traditional motors, while reliable, often fall short in optimizing power usage, leading to higher operational costs. In contrast, modern motor power systems, equipped with advanced technologies such as variable frequency drives and smart sensors, enable precise control of energy consumption. This transition not only reduces waste but also facilitates better integration within automated environments, where about 70% of gear applications are now utilized.

As industries shift towards automation, the demand for more efficient and sustainable energy solutions continues to grow. The development of innovative systems, such as electric and hybrid propulsion technologies, exemplify this trend. These modern alternatives are not only capable of meeting the stringent energy efficiency demands but also support the broader goals of sustainability in manufacturing processes. Consequently, investing in modern motor power technologies is essential for industries aiming to improve performance and reduce their carbon footprint.

The future of motor power in industrial applications is being shaped by a growing emphasis on sustainability and energy efficiency. As industries strive to reduce their carbon footprint, advancements in motor technology are playing a critical role. Innovations such as variable frequency drives (VFDs) and smart motor systems are becoming increasingly popular, enabling greater energy savings and optimized performance. These technologies not only enhance operational efficiency but also contribute to significant reductions in greenhouse gas emissions.

Furthermore, the integration of renewable energy sources within industrial settings is prompting a transformation in motor power usage. Electric motors are increasingly used in conjunction with solar and wind energy systems, making it imperative to focus on high-efficiency options. The trend towards electrification across various sectors, including transportation and manufacturing, is leading to the development of motors that are not only more efficient but also capable of adapting to fluctuating energy supplies. This shift not only underpins the drive for sustainable practices but also positions industries to meet future energy demands effectively.

Office: (281) 855-2218

Copyright © 2025 Telco Intercontinental Corp. All rights reserved. Privacy Policy | Legal Disclaimer

Telco®, TelcoMotion®, and TelcoGreen® are registered trademarks of Telco Intercontinental Corp.