Main Menu

In the ever-evolving landscape of industrial automation, maximizing efficiency is a fundamental goal for engineers and businesses alike. DC gear motors play a pivotal role in achieving this aim, merging the power of direct current with the precision of geared systems. These motors are designed to provide high torque at low speeds, making them ideal for a variety of applications, from robotics to conveyor systems. However, not all DC gear motors are created equal, and their performance can vary significantly based on design and application. In this blog, we will explore various strategies for optimizing the use of DC gear motors, comparing different types and configurations to help you make informed decisions that enhance operational efficiency. By understanding the unique features and benefits of each type, you can unlock the full potential of your systems and drive productivity to new heights.

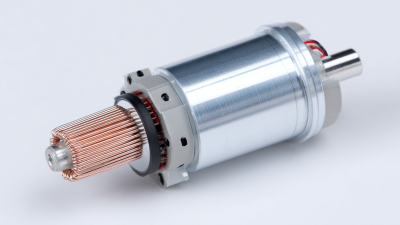

In the rapidly evolving landscape of modern automation systems, DC gear motors play a pivotal role in enhancing operational efficiency. These versatile components combine the benefits of direct current (DC) motors with gear reduction systems, allowing for precise control over speed and torque. This is particularly important in automated applications where accuracy and reliability are paramount. Industries ranging from manufacturing to robotics rely heavily on DC gear motors to streamline processes and reduce energy consumption, thus improving overall productivity.

The significance of DC gear motors is underscored by their ability to perform under varying load conditions while maintaining consistent performance. This adaptability makes them ideal for a myriad of applications, from conveyors and packaging machines to servo systems in robotics. As automation demands continue to escalate, the integration of DC gear motors ensures that systems can meet higher performance standards while minimizing wear and tear. Their compact design and impressive torque-to-size ratio also contribute to more efficient use of space and resources in automated setups, establishing them as indispensable elements in the quest for enhanced efficiency.

When evaluating the efficiency of DC gear motors, several key performance metrics can significantly influence system design and operational effectiveness. One of the primary metrics is the motor's efficiency rating, often expressed as a percentage that indicates how much of the input electrical energy is converted into useful mechanical energy. According to industry reports, high-efficiency DC gear motors can achieve ratings of over 90%. This efficiency not only reduces energy consumption but also lowers operational costs over the motor's lifespan.

Another crucial metric is the torque-to-weight ratio, which highlights the motor's performance relative to its size. Reports suggest that modern DC gear motors have improved this ratio considerably, allowing for compact designs that do not compromise on power delivery. For instance, manufacturers are now producing motors that offer a torque-to-weight ratio of 2.5 Nm/kg or higher. This improvement enables equipment designers to create lighter, more efficient machinery without sacrificing torque output, thereby enhancing overall system performance.

Additionally, thermal performance should also be measured, as excessive heat can lead to efficiency losses and component damage. High-quality DC gear motors are designed to operate at optimized temperatures, which can be verified through thermal imaging and specific heat measurements during testing. Implementing these performance metrics can ensure that businesses capitalize on the operational advantages offered by efficient DC gear motors.

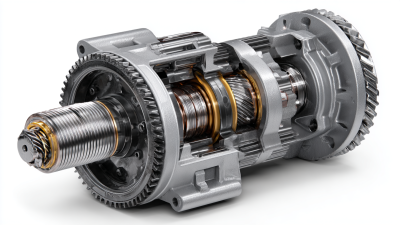

Innovative design techniques play a pivotal role in enhancing the performance of DC gear motors, ultimately maximizing efficiency.

With the growing demand for high-power, dense electrical machines, innovations such as hairpin windings have gained traction. These windings improve the mechanical efficiency of traction motors substantially. A recent comprehensive review highlights that optimizing design elements and employing advanced materials can reduce thermal stress and increase operational longevity, leading to significant gains in overall performance.

Tips for achieving optimal efficiency with DC gear motors include leveraging IoT for real-time monitoring and control. Implementing adaptive control strategies can further enhance motor operation, with studies showing that intelligent fault diagnosis systems can predict and prevent failures, thus reducing downtime.

Additionally, the integration of composite materials instead of traditional metals can lessen weight while maintaining structural integrity, contributing to improved overall performance.

By incorporating these innovative design techniques and considering material advancements, manufacturers can substantially improve the efficiency and reliability of DC gear motors, meeting the increasing demands of modern applications.

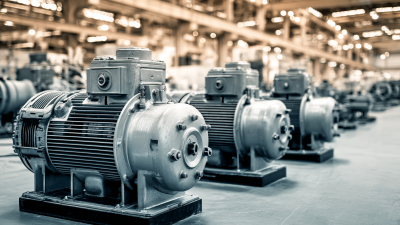

DC gear motors are increasingly recognized for their versatility and efficiency across various industries. In manufacturing, for instance, they are pivotal in automation solutions, enhancing productivity by up to 30% according to recent reports from the National Institute of Standards and Technology. Their ability to deliver high torque at low speeds makes DC gear motors ideal for tasks such as conveyor belt operations and robotic assembly lines. These motors not only streamline processes but also reduce energy consumption, aligning with sustainable production goals.

In the automotive industry, DC gear motors play a significant role in electric vehicles (EVs), contributing to improvements in efficiency and performance. A study by the International Energy Agency indicates that integrating advanced DC gear motors can significantly enhance the energy conversion efficiency of EV systems, leading to up to a 15% increase in overall vehicle range. Furthermore, their compact design allows for easier integration into various vehicle components, from power steering to automated window mechanisms, demonstrating their effectiveness in real-world applications beyond traditional use cases.

The future of DC gear motor technology is poised for significant advancements, driven by the increasing demand for energy-efficient solutions and automation in various industries. According to a report by Research and Markets, the global DC motor market is expected to grow at a CAGR of 5.2% from 2021 to 2026, highlighting the rising adoption of DC gear motors in sectors such as automotive, robotics, and consumer electronics. This growth reflects a broader trend toward miniaturization and improved performance, as manufacturers strive to develop more compact and powerful motors.

Innovations in materials and manufacturing processes are also contributing to advancements in DC gear motors. For instance, the introduction of high-strength composite materials not only reduces weight but also enhances durability and efficiency. Additionally, the integration of smart technology, such as IoT capabilities, is enabling real-time monitoring and precise control over motor operations. A study from Allied Market Research predicts that the smart motor market will surpass $15 billion by 2025, emphasizing the increasing need for intelligent solutions that optimize performance and energy usage.

As these technologies continue to evolve, we can expect DC gear motors to become even more versatile and efficient, meeting the diverse needs of modern applications.

Office: (281) 855-2218

Copyright © 2025 Telco Intercontinental Corp. All rights reserved. Privacy Policy | Legal Disclaimer

Telco®, TelcoMotion®, and TelcoGreen® are registered trademarks of Telco Intercontinental Corp.