Main Menu

In the realm of modern manufacturing, the role of industrial motors cannot be overstated. These vital components serve as the backbone of numerous processes, driving efficiency and productivity across various industries. According to Dr. Emily Johnson, a leading expert in industrial automation, "Industrial motors are not just components; they are the pulse of a manufacturing operation, ensuring precision and reliability at every turn." Her insight highlights the essential nature of these motors, which facilitate the seamless operation of machinery, from conveyor belts to CNC machines.

As manufacturing evolves with advanced technologies and automation, the demand for high-performance industrial motors continues to grow. These motors are designed to handle diverse applications, delivering the power and efficiency needed to optimize production lines. With features like energy efficiency and durability, industrial motors not only enhance productivity but also contribute to sustainable manufacturing practices. Embracing state-of-the-art industrial motors enables businesses to remain competitive in a rapidly changing market, fostering innovation and reducing operational costs. Through this lens, it becomes clear that industrial motors are indispensable for efficient manufacturing processes, driving the industry towards a more productive and environmentally responsible future.

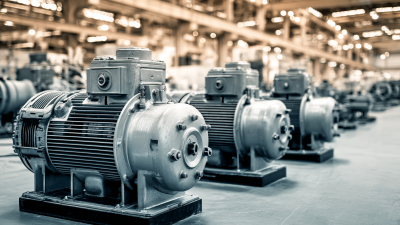

Industrial motors play a pivotal role in modern manufacturing, serving as the driving force behind a wide array of processes and machinery. These motors are designed to convert electrical energy into mechanical energy, facilitating the operation of equipment such as conveyor belts, pumps, and compressors. Their efficiency and reliability are critical for maintaining production schedules and optimizing workflow, ensuring that operations run smoothly without unnecessary downtime.

Furthermore, the integration of advanced technologies in industrial motors has significantly enhanced their performance and functionality. Features such as variable speed control and energy monitoring allow manufacturers to fine-tune their processes, reducing energy consumption and increasing productivity. By automating tasks and improving precision, modern industrial motors contribute significantly to the overall efficiency of manufacturing systems. This technological evolution underscores the importance of selecting the right motor for specific applications, as it can lead to substantial improvements in both operational effectiveness and cost savings.

Industrial motors play a critical role in manufacturing processes, driving efficiency and precision across various applications. There are several types of industrial motors utilized in these settings, each tailored to specific tasks. The most common types include AC (alternating current) motors, DC (direct current) motors, servo motors, and stepper motors. According to the International Electrotechnical Commission (IEC), AC motors account for approximately 70% of all industrial motor applications, making them the backbone of manufacturing operations due to their durability, efficiency, and low maintenance requirements.

AC motors are frequently used for constant-speed applications like conveyor belts and pumps, while DC motors are preferred in situations requiring variable speed and high torque, such as in robotic arms. On the other hand, servo motors provide precise control of angular position and are ideal for applications in CNC machines and automated assembly lines. Stepper motors, known for their ability to move in discrete steps, are commonly used in 3D printers and other applications requiring accuracy.

Tips: When selecting an industrial motor, consider factors such as load requirements, speed, and environmental conditions. Regular maintenance is crucial for ensuring the longevity and performance of motors—implement a preventive maintenance schedule to minimize downtime. Furthermore, investing in energy-efficient motors can lead to significant cost savings, as they consume less power while maintaining high performance levels.

| Type of Industrial Motor | Typical Applications | Power Range (kW) | Efficiency Rating | Advantages |

|---|---|---|---|---|

| AC Motors | Pumps, Fans, Conveyors | 0.1 - 500 | IE1 to IE5 | Durability, Low Maintenance |

| DC Motors | Electric Vehicles, Robotics | 0.01 - 200 | IE2 to IE4 | High Torque, Precise Control |

| Servo Motors | CNC Machines, Robotics | 0.1 - 300 | IE3 to IE5 | High Precision, Quick Response |

| Stepper Motors | 3D Printers, Automation | 0.01 - 100 | IE2 to IE4 | Simple Control, High Resolution |

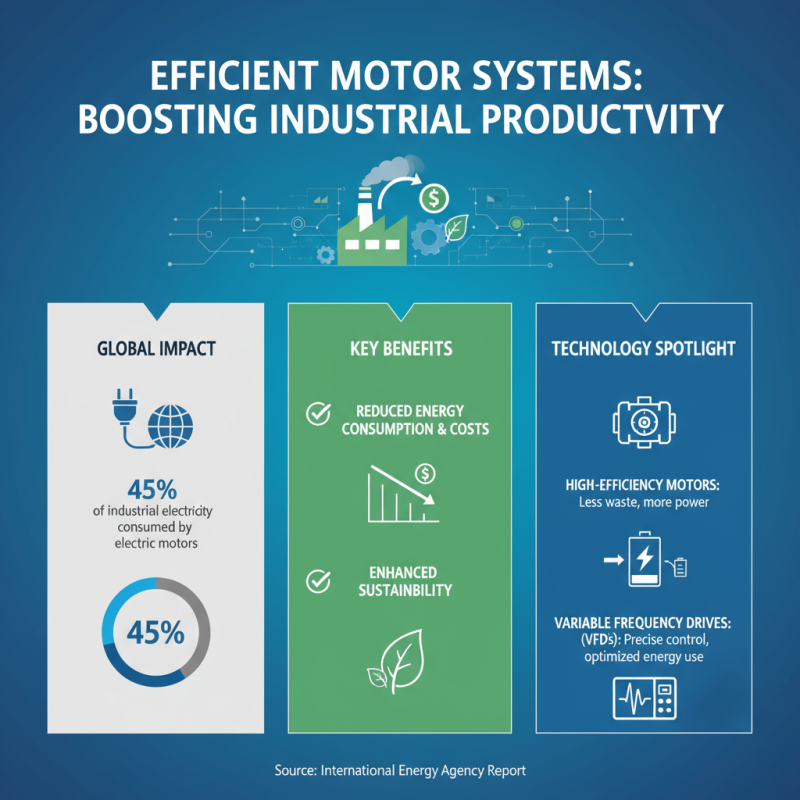

Efficient motor systems play a pivotal role in enhancing production efficiency within industrial manufacturing processes. According to a report by the International Energy Agency, electric motors account for approximately 45% of global electricity consumption in the industrial sector. This highlights the significant impact that motor efficiency has on overall energy use and operational costs. By utilizing high-efficiency motors, manufacturers can reduce energy consumption, which is not only cost-effective but also contributes to sustainability goals. The incorporation of variable frequency drives (VFDs) further enhances motor efficiency by allowing precise control of motor speed and torque, resulting in optimized energy usage across varying load conditions.

Moreover, adopting advanced motor technologies can lead to substantial gains in productivity. A study from the U.S. Department of Energy indicates that upgrading to premium efficiency motors can yield energy savings of 2-8% compared to standard motors, translating into thousands of dollars saved annually for medium to large-scale operations. These savings can be reinvested into other areas of production, facilitating further enhancements in manufacturing processes. Additionally, efficient motors often require less maintenance, leading to reduced downtime and higher overall equipment effectiveness (OEE). With the current emphasis on Industry 4.0, integrating smart motor solutions not only boosts efficiency but also enables predictive maintenance, ensuring optimal operational workflow and minimizing disruptions in production lines.

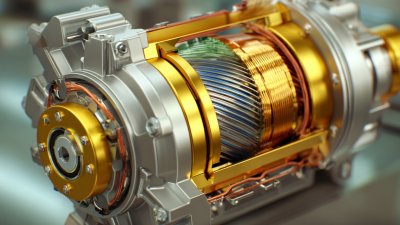

The advancements in motor technology have been a significant driver of growth in the manufacturing sector. With the integration of smart motors and variable frequency drives (VFDs), manufacturing processes have become more energy-efficient and capable of fine-tuning operations to meet specific production demands. According to a report published by the International Energy Agency, the adoption of advanced motor technologies can lead to energy savings of up to 30%, thereby reducing operational costs significantly.

Furthermore, the latest innovations in motor design are contributing to higher reliability and reduced maintenance costs. For instance, permanent magnet synchronous motors (PMSMs) are gaining traction due to their enhanced efficiency and performance compared to traditional induction motors. These motors are typically 10-15% more efficient, which translates into substantial savings over time for manufacturers, especially those operating in energy-intensive industries.

**Tips:** When considering motor upgrades, assess the total cost of ownership rather than just the initial purchase price. Implementing advanced motor systems may require initial investment, but the long-term savings in energy and maintenance often outweigh these costs. Additionally, regular training for staff on the latest motor technologies can ensure that your teams are well-equipped to leverage these advancements effectively, ultimately enhancing productivity.

The integration of industrial motors in manufacturing processes is often accompanied by a set of challenges that can impede efficiency and productivity. One of the most pressing issues is energy consumption. According to a report by the International Energy Agency (IEA), industrial motors account for approximately 65% of the total electricity consumed in industrial applications. As such, inefficient motor operations can lead to significant energy losses, driving up operational costs.

To address these challenges, manufacturers are turning to advanced motor technologies and better implementation strategies. The use of variable frequency drives (VFDs), for instance, allows for precise control over motor speeds and reduces energy wastage. Furthermore, regular maintenance schedules and predictive analytics can minimize downtime by identifying potential failures before they occur. According to a study by the U.S. Department of Energy, proper maintenance procedures can improve motor efficiency by up to 15%.

Tips:

1. Invest in energy-efficient motors that comply with international efficiency standards to lower energy costs.

2. Implement regular maintenance and monitoring systems to ensure optimal performance and longevity of motors.

By tackling these challenges head-on, manufacturers can not only enhance the efficiency of their processes but also contribute to a more sustainable industrial ecosystem.

Office: (281) 855-2218

Copyright © 2025 Telco Intercontinental Corp. All rights reserved. Privacy Policy | Legal Disclaimer

Telco®, TelcoMotion®, and TelcoGreen® are registered trademarks of Telco Intercontinental Corp.