Main Menu

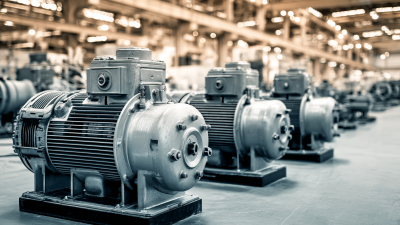

In today's industrial landscape, the choice of the right 240 volt motor is crucial for optimizing efficiency and productivity. According to a recent report from the Electric Power Research Institute, nearly 70% of industrial electricity consumption is attributed to motor-driven systems, highlighting the significant impact that motor selection can have on operational costs and energy efficiency. Furthermore, the U.S. Department of Energy estimates that upgrading to high-efficiency motors can yield savings of up to 15% on energy bills. With various alternatives available in the market, selecting the best motor for your business requires careful consideration of several factors, including load requirements, environmental conditions, and operational efficiency. This blog delves into five essential tips for ensuring that you choose the right 240 volt motor that will not only meet your operational demands but also contribute to a more sustainable energy future.

When selecting the right 240 Volt motor for your business, understanding the implications of voltage is crucial. The voltage rating of a motor directly influences its efficiency, performance, and compatibility with existing equipment. Higher voltage motors can offer lower currents, which reduces the risk of overheating and can lead to better energy efficiency. Ensuring that your motor meets the requirements of your specific applications is essential, particularly in industrial settings where improper voltage can cause severe operational issues.

Tip 1: Always check the motor's voltage ratings and match them with your business's electrical supply to avoid mismatches that could lead to inefficiencies or equipment failure.

Tip 2: Consider the environment where the motor will be used. For instance, in mining or industrial applications, utilizing soft starters can be beneficial to manage inrush currents and prolong motor life.

By carefully evaluating voltage requirements and understanding their importance, businesses can ensure they select the right motor to meet their operational needs.

When selecting the right 240 Volt motor for your business, there are several key factors to consider. Firstly, understanding the load requirements is crucial. According to the National Electrical Manufacturers Association (NEMA), selecting a motor with the right horsepower and duty cycle can significantly enhance operational efficiency and reduce energy costs. For instance, a motor that operates under constant load conditions can be more energy-efficient compared to one that is frequently throttled, potentially leading to a 10-20% reduction in energy consumption.

Another significant factor is the environmental conditions where the motor will be operating. The Motor & Equipment Manufacturers Association (MEMA) suggests considering parameters such as temperature, humidity, and exposure to dust or chemicals. These conditions can affect the motor's lifespan and performance. Investing in a motor with appropriate protection ratings (like IP ratings) can prevent premature failures and ensure that your operations run smoothly. A detailed inspection of these factors can lead to a more sound investment, as statistics indicate that businesses not properly considering these variables may incur maintenance costs up to 30% higher over time.

When selecting a 240 volt motor, understanding its common applications across various industries is crucial. For instance, in manufacturing, 240 volt motors are widely used in conveyor systems and large machinery. According to a report by the National Electrical Manufacturers Association (NEMA), approximately 40% of industrial motor systems use 240 volt motors to achieve optimal performance with efficiency ratings of up to 95%. These motors prove essential for ensuring high productivity and minimizing energy costs.

In the HVAC industry, 240 volt motors drive air conditioning units and heating systems. A study by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) indicates that using the right motor size and type can enhance system efficiency by up to 30%. When choosing a motor for such applications, consider Tip 1: Evaluate your power requirements to avoid misapplications and potential energy loss.

Additionally, 240 volt motors are commonplace in agriculture for powering equipment like irrigation pumps and grain augers. Research from the Agricultural Engineering Society shows that optimizing motor selection can improve energy savings by 25%. Hence, another valuable Tip is to consider the environment in which the motor will operate, ensuring it is designed to withstand specific conditions while delivering the required power.

When selecting a 240 Volt motor, assessing the compatibility with existing equipment is crucial for seamless integration and optimized performance. According to the National Electric Motor Association (NEMA), over 60% of industrial facilities experience production delays due to incompatible motor systems. To avoid costly downtime, take a thorough inventory of your current machinery, noting existing motor specifications and operational requirements. Pay special attention to voltage ratings, phase configuration, and size, as mismatches in these areas can lead to inefficiencies or outright failure.

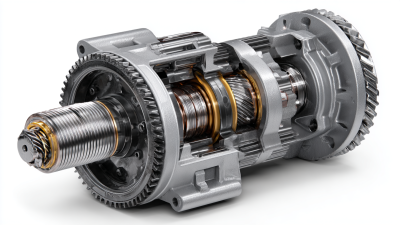

Moreover, it's essential to consider the control systems in place. A report from the Electric Power Research Institute (EPRI) highlights that nearly 40% of businesses underestimate the technological requirements of integrating new motors with their automation practices. Ensure that the new motor's control capability aligns with your existing systems, including variable frequency drives (VFDs) or programmable logic controllers (PLCs). Conducting a compatibility analysis may also involve consulting with motor manufacturers or technical experts to gain insights on expected performance and longevity within your specific application. This careful evaluation will not only enhance performance but also extend the lifespan of your entire operation.

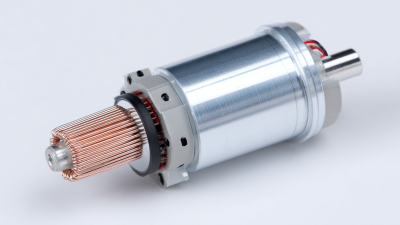

When selecting a 240 Volt motor for your business, evaluating its efficiency and performance ratings is crucial. According to the U.S. Department of Energy, electric motors account for approximately 65% of industrial electricity consumption. This makes the choice of motor not only a technical consideration but also an important factor in energy management and cost savings. Motors that are rated as Premium Efficiency (IE3 or higher) can save up to 8% in energy costs compared to standard efficiency models. This can translate into significant savings, especially in applications running continuously or at high loads.

When assessing performance ratings, pay close attention to the motor's service factor and temperature rise ratings. A motor with a service factor of 1.15 can handle 15% more than its rated load without overheating, offering flexibility and longevity in demanding applications. Additionally, the National Electrical Manufacturers Association (NEMA) provides standardized service and temperature ratings that help businesses determine appropriate operational conditions. Selecting the right motor based on these criteria can enhance not only operational efficiency but also the overall lifespan and reliability of your equipment.

| Motor Type | Power Rating (HP) | Efficiency (%) | Service Factor | Frame Size |

|---|---|---|---|---|

| AC Induction Motor | 10 | 90 | 1.15 | NEMA 254T |

| Brushless DC Motor | 5 | 92 | 1.2 | NEMA 143T |

| Synchronous Motor | 15 | 95 | 1.0 | NEMA 324T |

| Single-Phase Motor | 3 | 85 | 1.0 | NEMA 48 |

| Variable Frequency Drive (VFD) Motor | 7.5 | 93 | 1.1 | NEMA 182T |

Office: (281) 855-2218

Copyright © 2025 Telco Intercontinental Corp. All rights reserved. Privacy Policy | Legal Disclaimer

Telco®, TelcoMotion®, and TelcoGreen® are registered trademarks of Telco Intercontinental Corp.