Main Menu

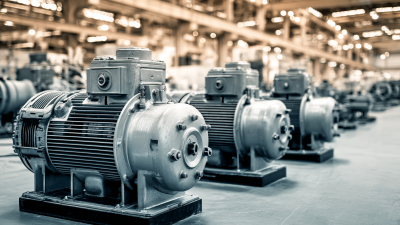

In the ever-evolving landscape of manufacturing, the focus on enhancing efficiency has led to significant advancements in the performance of industrial AC motors. According to a recent report by the International Energy Agency, electric motors account for nearly 70% of industrial electricity consumption, highlighting the critical need for optimization in this sector. By improving the design and operational parameters of industrial AC motors, manufacturers can achieve considerable energy savings while boosting productivity. Techniques such as effective motor sizing, regular maintenance, and the implementation of variable frequency drives (VFDs) can lead to energy savings of up to 30%. As the demand for sustainable practices increases, understanding the intricacies of industrial AC motor performance becomes essential for manufacturers aiming to reduce operational costs and enhance competitiveness in a global market driven by efficiency.

In the ever-evolving landscape of manufacturing, the focus on enhancing efficiency has led to significant advancements in the performance of industrial AC motors. According to a recent report by the International Energy Agency, electric motors account for nearly 70% of industrial electricity consumption, highlighting the critical need for optimization in this sector. By improving the design and operational parameters of industrial AC motors, manufacturers can achieve considerable energy savings while boosting productivity. Techniques such as effective motor sizing, regular maintenance, and the implementation of variable frequency drives (VFDs) can lead to energy savings of up to 30%. As the demand for sustainable practices increases, understanding the intricacies of industrial AC motor performance becomes essential for manufacturers aiming to reduce operational costs and enhance competitiveness in a global market driven by efficiency.

The efficiency of industrial AC motors is crucial for optimizing performance and achieving significant energy savings in manufacturing processes. A pivotal aspect of enhancing efficiency lies in understanding the key components of these motors. According to the latest Global Market Analysis Report, the electric motor market is projected to reach USD 285.9 billion by 2035, reflecting a strong growth trend driven by advances in technology and the increasing demand for energy-efficient solutions. Key efficiency levels recognized in this sector include IE3 and IE4, which promise reduced energy consumption and improved operational output.

Recent studies have also highlighted innovative approaches to enhance motor performance across various applications. For instance, research has shown that direct torque control in doubly fed induction motors can be significantly improved using artificial neural networks, resulting in heightened responsiveness and energy efficiency, particularly in electric vehicles. Moreover, the Energy Efficient Motor Market is expected to grow along with advancements in BLDC motor drives, focusing on hybrid optimization algorithms to increase power efficiency in applications such as drones. This ongoing evolution in motor technology underscores the industry's commitment to both performance and sustainability in an increasingly competitive landscape.

The global IoT energy management market is poised for significant growth, projected to expand from $70.58 billion in 2023 to $222.56 billion by 2030, reflecting a compound annual growth rate of 17.8%. This surge is primarily driven by the urgent need for manufacturing facilities to optimize energy consumption patterns. As businesses grapple with rising operational costs and seek to minimize their environmental footprints, efficient energy management systems, increasingly incorporating artificial intelligence, are becoming essential. The AI energy management market itself is experiencing an unprecedented demand across various sectors, indicating a profound shift towards energy efficiency.

Moreover, as the landscape of energy consumption evolves, the rise of electrification marks a pivotal milestone in the transition to cleaner energy sources. With electricity emerging as a high-efficiency and versatile secondary energy source, it not only replaces traditional fossil fuel-based methods but also catalyzes advancements in renewable applications like electric vehicles. This transformation aligns with China's dual carbon goals, emphasizing the importance of green electricity connections to meet industry demands and enhance the deployment of renewable energy, thus further contributing to cost reduction and sustainable development in manufacturing facilities.

The implementation of IoT solutions for real-time monitoring and optimization of industrial AC motors stands at the forefront of enhancing operational efficiency in manufacturing. The integration of smart motor sensors, projected to grow from a market value of $150 million in 2022 to $450 million by 2030, reflects a robust compound annual growth rate (CAGR) of 15% from 2024 to 2030. This growth underscores the increasing demand for sophisticated monitoring technologies that can deliver critical performance insights for improved energy efficiency in industrial operations.

In the context of smart cities and advanced industrial automation, the convergence of IoT and cloud technologies is revolutionizing production environments. For instance, initiatives facilitating real-time data access enable manufacturers to make quick decisions concerning motor performance, thereby reducing downtime and operational costs. Leveraging intelligent data solutions ultimately helps optimize energy use, aligning with the broader industry trend of sustainable manufacturing practices. With enhanced visibility into equipment performance, companies can not only track efficiency metrics but also implement predictive maintenance strategies that significantly reduce energy waste and extend the lifespan of their motors.

| Metric | Value | Unit | Notes |

|---|---|---|---|

| Motor Efficiency | 92 | % | Baseline efficiency measurement |

| Annual Energy Consumption | 500,000 | kWh | Estimated energy usage |

| Annual Cost Savings | 30,000 | USD | Based on efficiency improvements |

| Sensor Accuracy | 99 | % | Real-time monitoring |

| Data Update Frequency | 1 | Second | Real-time analytics |

| Mean Time Between Failures | 10,000 | Hours | Reliability metric |

| Return on Investment | 150 | % | Investment analysis |

Variable Frequency Drives (VFDs) have become a critical component in optimizing energy savings for industrial AC motors. These devices allow for precise control of motor speed and torque, significantly enhancing operational efficiency. According to a report by the U.S. Department of Energy, VFDs can improve energy efficiency by 20-50% in variable-load applications, leading to substantial reductions in energy costs for manufacturing facilities. By adjusting the power supplied to the motor based on real-time demand, VFDs minimize energy waste and extend the lifespan of equipment.

The impact of VFD implementation on energy savings is further underscored by a study conducted by the National Renewable Energy Laboratory, which indicates that integrating VFDs can reduce the electricity consumption of motors by approximately 30%, especially in centrifugal pump and fan systems. This not only translates to lower operational expenses but also contributes to sustainability efforts within industries. Many manufacturers are recognizing these benefits, with the U.S. market for VFDs projected to grow at a compound annual growth rate (CAGR) of 7.9% from 2021 to 2028, reflecting the ongoing shift towards more energy-efficient technologies in the industrial sector.

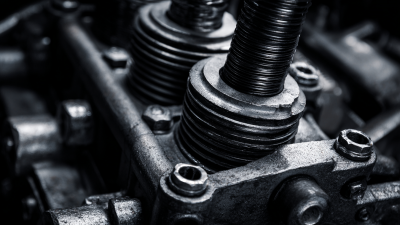

Regular maintenance is crucial for prolonging the lifespan and efficiency of industrial AC motors. By implementing best practices, manufacturers can prevent costly breakdowns and maintain optimal performance. One effective approach is to establish a routine inspection schedule that includes checking for wear and tear on components such as bearings and windings. Additionally, ensuring that the motor is clean and free of dust and debris can significantly improve airflow and cooling, which are vital for efficient operation.

Another essential maintenance practice is to monitor the electrical connections and supply voltage regularly. Loose connections can lead to overheating and reduced efficiency, ultimately shortening the motor's lifespan. Furthermore, utilizing vibration analysis can help identify potential issues before they escalate, allowing for timely interventions and repairs. By prioritizing these maintenance strategies, manufacturers can enhance the reliability of their AC motors, resulting in improved productivity and significant energy savings in the long run.

The chart displays the energy consumption of industrial AC motors before and after implementing regular maintenance practices. By optimizing performance through maintenance, energy savings of 30% can be achieved, showcasing the importance of regular upkeep in enhancing efficiency.

Office: (281) 855-2218

Copyright © 2025 Telco Intercontinental Corp. All rights reserved. Privacy Policy | Legal Disclaimer

Telco®, TelcoMotion®, and TelcoGreen® are registered trademarks of Telco Intercontinental Corp.