Main Menu

In the ever-evolving landscape of industrial machinery, the selection of the right drive system is critical for achieving optimal performance and efficiency. Gear drive motors have emerged as a pivotal choice for numerous applications, thanks to their robust design and superior power transmission capabilities. According to a recent industry report by ResearchAndMarkets, the global market for gear drive motors is projected to grow at a CAGR of 5.3% from 2021 to 2026, reflecting the increasing demand for high-efficiency solutions in sectors such as manufacturing, automotive, and robotics. These motors not only enhance operational efficiency but also reduce mechanical wear and energy consumption. As industries strive for greater productivity and sustainability, understanding the compelling reasons to choose gear drive motors becomes essential for informed decision-making. This blog aims to delve into seven key benefits that highlight why incorporating gear drive motors is a strategic investment for optimal performance.

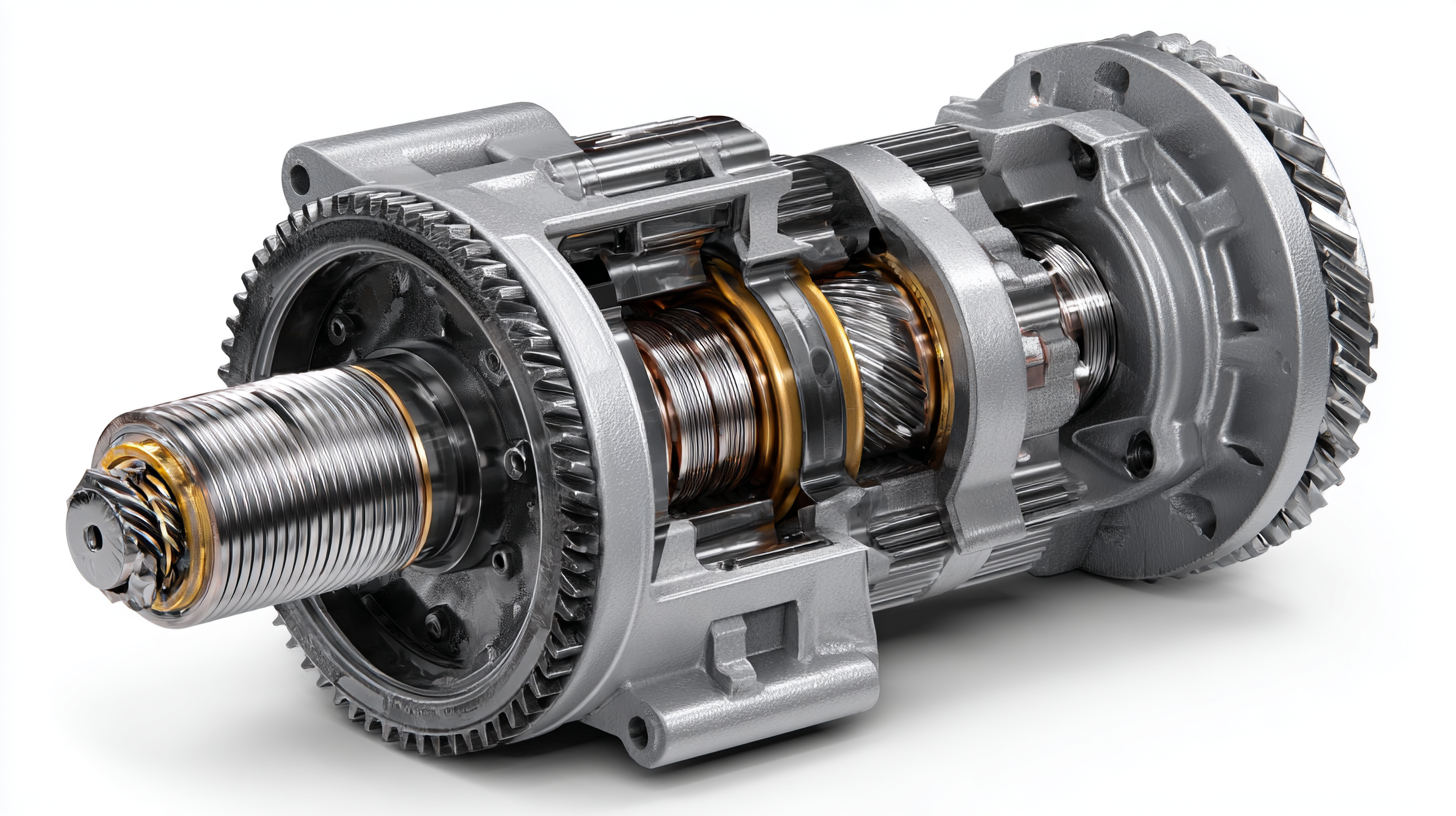

Gear drive motors are increasingly preferred in various applications due to their distinct advantages over other motor types. One key advantage is their ability to deliver high torque at lower speeds, making them ideal for heavy-duty tasks in manufacturing and logistics. Compared to AC and DC motors, gear drive motors excel in efficiency, especially for applications requiring consistent performance under load. Their compact design allows for easier integration into machinery, maximizing space utilization and simplifying installation processes.

Gear drive motors are increasingly preferred in various applications due to their distinct advantages over other motor types. One key advantage is their ability to deliver high torque at lower speeds, making them ideal for heavy-duty tasks in manufacturing and logistics. Compared to AC and DC motors, gear drive motors excel in efficiency, especially for applications requiring consistent performance under load. Their compact design allows for easier integration into machinery, maximizing space utilization and simplifying installation processes.

When selecting a motor, consider the voltage specifications based on your application requirements. Gear drive motors are available in a range of power outputs, accommodating systems requiring fractional horsepower to those needing full horsepower capabilities. For optimal performance, always check the power source compatibility, particularly with high-voltage setups that can affect efficiency.

Tip: Always analyze the specific torque and speed requirements of your application to select the right gear ratio, ensuring the motor operates within its efficient range. Additionally, regular maintenance can significantly enhance the lifespan and reliability of gear drive motors, making them a smart investment for long-term performance.

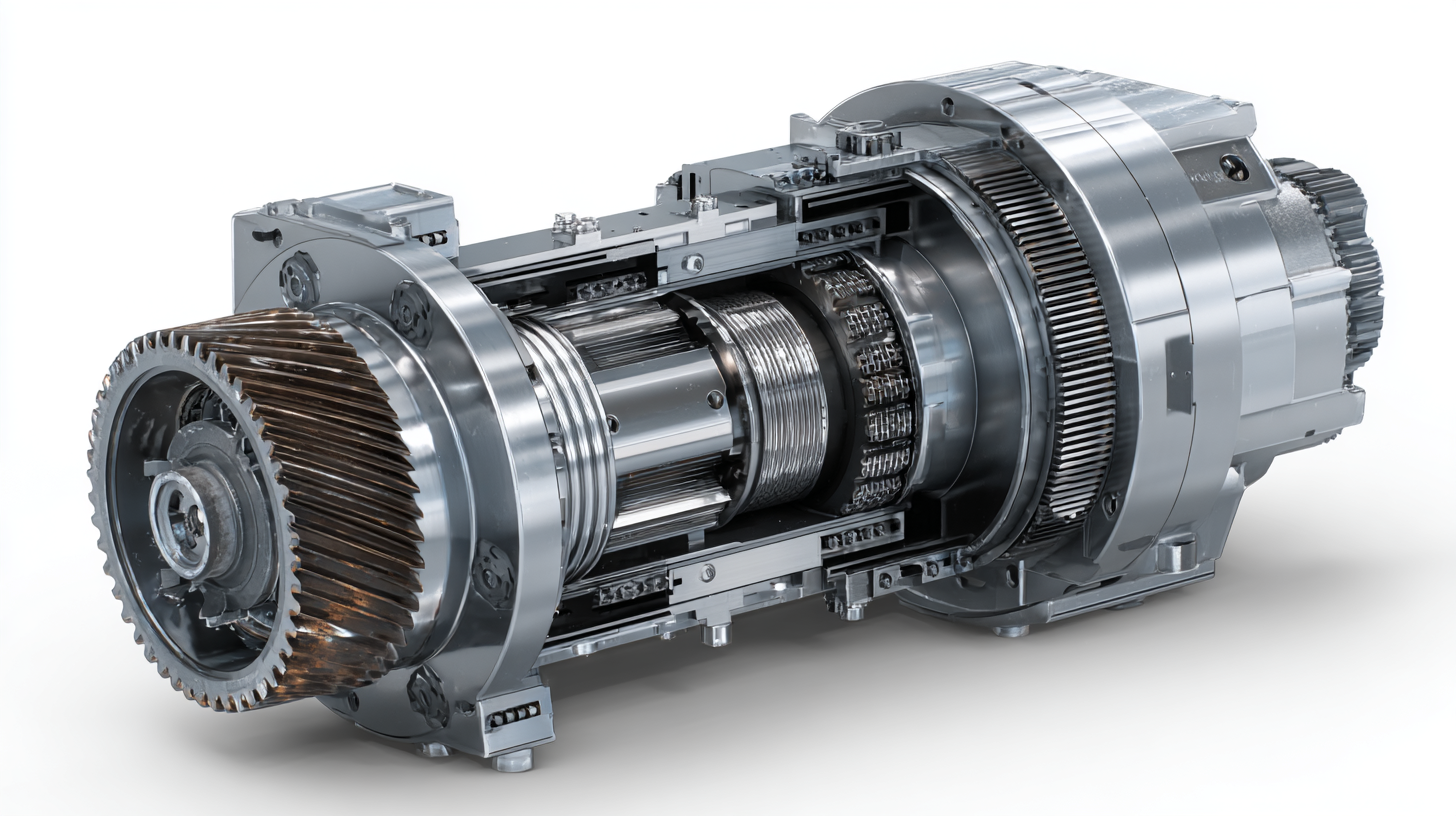

Gear drive motors have become a top choice for industries seeking enhanced performance and efficiency. These motors leverage a system of gears that translate high-speed energy from the motor into increased torque, enabling machinery to operate more effectively across various applications. This transformation not only minimizes energy loss but also ensures that more power is available for productive use. By optimizing the torque output, gear drive motors provide a robust solution for applications requiring precision and reliability.

Furthermore, the design of gear drive motors improves overall mechanical efficiency. Unlike direct drive systems, which can suffer from energy dissipation due to friction and heat, gear drive systems maintain a high efficiency by employing gear ratios tailored to specific tasks. This enhances not only the performance but also the longevity of the equipment, leading to reduced maintenance costs. As industries evolve and demand more from their machinery, the ability of gear drive motors to sustain optimal performance through effective power management has made them an indispensable component in modern engineering solutions.

When it comes to selecting motors for industrial applications, durability is a critical factor that cannot be overlooked. Gear drive motors are recognized for their exceptional longevity, which stems from their robust construction and efficient design. The intricate gear system within these motors facilitates smoother power transmission, minimizing wear and tear. This design not only extends the life of the motor but also ensures consistent performance under various loads and conditions, making them an ideal choice for demanding environments.

In addition to their inherent durability, gear drive motors are engineered to withstand harsh operational settings. Whether exposed to extreme temperatures, vibrations, or corrosive environments, these motors are built to endure. Their sealed components and high-quality materials contribute to their resilience, further enhancing their lifespan. Choosing gear drive motors means investing in a solution that prioritizes reliability and longevity, ensuring that your operations run seamlessly and efficiently for years to come. This commitment to durability translates into reduced maintenance costs and less frequent replacements, ultimately benefiting your bottom line.

Gear drive motors are exceptional in a variety of applications, making them a go-to choice for industries looking to enhance performance and efficiency. One area where gear drive motors truly shine is in heavy-duty machinery, such as construction and mining equipment. Their ability to deliver high torque at low speeds enables these powerful machines to operate effectively, even in the most demanding conditions. This characteristic not only improves productivity but also extends the lifespan of the equipment, as the motors can handle significant stress without compromising performance.

In addition to heavy machinery, gear drive motors are widely used in automation and robotics. The precision and control they offer make them ideal for applications that require exact movements and repetitive tasks. This versatility is particularly crucial in manufacturing environments, where gear drive motors help streamline processes by improving accuracy and reducing downtime. Furthermore, these motors can be customized for specific operational needs, further enhancing their effectiveness across various sectors, including food processing, packaging, and material handling.

| Application Area | Benefits of Gear Drive Motors | Key Specifications | Typical Torque Range |

|---|---|---|---|

| Industrial Automation | High efficiency and durability | Power: 0.5-100 kW, Speed: 10-5000 RPM | 10-200 Nm |

| Conveyor Systems | Smooth operation and load handling | Power: 1-50 kW, Speed: 5-200 RPM | 20-300 Nm |

| Pumping Applications | Consistent flow and high torque | Power: 0.5-75 kW, Speed: 10-1500 RPM | 15-400 Nm |

| Material Handling | High torque for heavy loads | Power: 0.5-200 kW, Speed: 1-300 RPM | 30-600 Nm |

| Agricultural Machinery | Reliability in tough conditions | Power: 1-150 kW, Speed: 5-2000 RPM | 25-500 Nm |

| Construction Equipment | High torque and reliability | Power: 5-300 kW, Speed: 10-1500 RPM | 50-800 Nm |

When evaluating the cost-effectiveness of gear drive motors, it's crucial to consider their long-term savings potential. While the initial investment may be higher compared to other motor types, gear drive motors offer significant advantages in energy consumption and maintenance costs. Their efficient design reduces energy losses during operation, resulting in lower electricity bills over time. This efficiency is particularly beneficial for industrial applications, where energy costs can substantially impact overall operational expenses.

Additionally, gear drive motors typically require less frequent maintenance due to their robust construction and sealed designs. This longevity translates to reduced downtime and maintenance schedules, which can save businesses considerable sums over years of operation. When you factor in the reliability and durability of gear drive motors, their cost-effectiveness becomes apparent. Companies investing in these motors can experience enhanced productivity and operational efficiency while simultaneously enjoying the financial benefits of lower maintenance and energy costs.

Office: (281) 855-2218

Copyright © 2025 Telco Intercontinental Corp. All rights reserved. Privacy Policy | Legal Disclaimer

Telco®, TelcoMotion®, and TelcoGreen® are registered trademarks of Telco Intercontinental Corp.