Main Menu

Motion control motors are integral to modern automation systems, powering everything from robotics to aerospace applications. As the industry grows—projected to reach $29.4 billion by 2025, with a compound annual growth rate (CAGR) of 7.5%—challenges in performance, efficiency, and reliability are becoming more pronounced.

Manufacturers experience issues such as overheating, noise interference, and integration complexities, which hinder optimal functionality. Recent research indicates that nearly 30% of motion control projects face delays due to control system inefficiencies.

Addressing these common challenges involves not only understanding the specific requirements of different applications but also leveraging innovative solutions such as advanced control algorithms and smart motor technologies. This blog will explore these common hurdles and provide insights into effective strategies for leveraging motion control motors to enhance performance and productivity in various sectors.

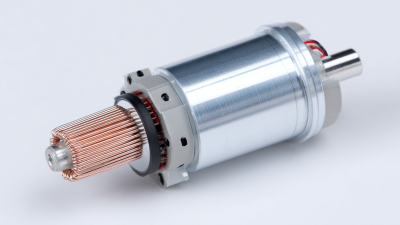

Motion control motors play a crucial role in various applications, from industrial automation to the automotive sector. Key factors impacting their performance include motor efficiency, response time, and integration capabilities. Recent advancements have emphasized the importance of optimizing motor efficiency, which not only enhances energy savings but also contributes to sustainability in motion control systems. Efficient motors can significantly lower operational costs and improve overall system performance, making them essential for modern automation solutions.

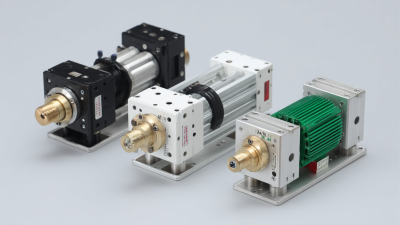

Moreover, the evolution of motion control systems is evidenced by the integration of advanced technologies that allow for precision and flexibility. Innovations such as servo-electric test systems have transformed quality assurance processes in the automotive industry, enabling manufacturers to achieve higher standards of performance and reliability. Integration with state-of-the-art control systems allows manufacturers to conduct thorough testing and adjustments, ensuring that their motion control solutions are both robust and responsive to varying operational demands. As industries continue to demand greater precision and efficiency, understanding these key factors will be pivotal for engineers and designers working with motion control motors.

This chart illustrates the key factors impacting motion control motor performance. Each factor is assessed on a scale from 1 to 10, with higher numbers indicating a greater level of impact on the overall functionality and performance of motion control systems.

Motion control motors are integral to various industrial applications, but they often face common issues that can significantly affect performance and reliability. According to a report by the Motor & Motion Control Manufacturers Association, approximately 30% of motor failures in industrial settings can be attributed to overheating. This is frequently caused by inadequate thermal management or overly aggressive acceleration profiles. Understanding these root causes is crucial for optimizing performance and ensuring the longevity of motion control systems.

Another prevalent challenge is the risk of misalignment, which can lead to increased wear and tear on bearings and gears. The 2022 Global Motion Control Market Report emphasizes that misalignment is responsible for nearly 25% of mechanical failures in motion control applications. Proper installation and regular maintenance are essential to mitigate these risks. Real-time monitoring technologies, such as vibration analysis and temperature sensors, can provide valuable insights into the operational status of motors, allowing for timely interventions before minor issues escalate into significant problems. Deploying these solutions can enhance efficiency and minimize downtime, ultimately leading to improved productivity across various industries.

The motion control motor industry is facing several challenges as it strives to keep pace with the growing demand driven by advancements in technology and sustainability initiatives. According to recent market analysis, the global three-phase AC motor market is projected to reach $17.3 billion in 2024, with an anticipated growth to $18.7 billion by 2033, reflecting a compound annual growth rate during this forecast period. This indicates a robust need for effective solutions to overcome the challenges in motion control.

Moreover, the rise of battery electric vehicles (BEVs) has further heightened the importance of reliable motion control systems as they serve as the backbone of electric drive systems. With increased focus on environmental sustainability, the development of advanced drive systems is essential for the acceleration of BEVs in the market. Manufacturers need to address technical hurdles such as integration of high-performance control algorithms and minimizing energy losses in motor systems to ensure they meet the rigorous demands of today's applications. Overall, insights from industry leaders could yield significant improvements in design and functionality, ultimately enhancing the overall motion control landscape.

The landscape of motion control solutions is rapidly evolving, driven by innovative technologies that enhance precision, flexibility, and efficiency in industrial automation. Recent advancements have showcased how digitalisation and electrification are key in redefining traditional motor control approaches. For instance, the latest solutions emphasize load and source management, essential for ensuring optimal operation and preventive maintenance protocols.

Moreover, companies are increasingly focusing on high-performance motor control technologies that cater to specific industry needs. With market research projecting a growth rate of over 7% in the motion control market by 2025, organizations are investing heavily in R&D to remain competitive. The introduction of autonomous and intelligent motor control systems illustrates a crucial shift toward seamless automation, highlighting a growing trend of integrating artificial intelligence to enhance system responsiveness.

As the industry witnesses a surge in collaboration, such as strategic partnerships with investment firms, the access to innovative solutions becomes more pronounced. This synergy not only accelerates the development of cutting-edge technologies but also expands market reach, particularly in emerging economies where the demand for advanced motion control solutions is on the rise.

In the realm of motion control systems, effective maintenance and optimization practices are crucial for enhancing performance and extending equipment lifespan. Recent trends indicate that the global market for Intelligent Motion Control Centers (IMCC) is rapidly expanding, driven by an increasing demand for energy efficiency across various industries. Reports suggest that by 2032, the IMCC market is expected to reach significant revenue milestones, highlighting the necessity for robust maintenance strategies that ensure system reliability and operational excellence.

Best practices for the maintenance of motion control systems include regular diagnostics, routine software updates, and continuous performance monitoring. These methodologies have been shown to decrease system downtime and optimize efficiency by up to 30%. Furthermore, integrating advanced analytics can provide deeper insights into equipment performance, allowing for predictive maintenance approaches that address potential issues before they escalate into costly failures.

As the industry moves towards more intelligent and interconnected systems, these practices will be integral in fostering innovation and maintaining competitive advantage in the evolving landscape of motion control technologies.

Office: (281) 855-2218

Copyright © 2025 Telco Intercontinental Corp. All rights reserved. Privacy Policy | Legal Disclaimer

Telco®, TelcoMotion®, and TelcoGreen® are registered trademarks of Telco Intercontinental Corp.