Main Menu

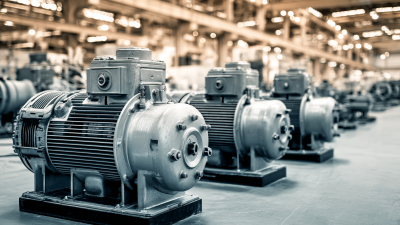

Choosing the right motor power motor for industrial applications is crucial for optimizing performance and ensuring efficiency in operations. According to a recent report by the International Electrotechnical Commission, the global electric motor market is projected to reach $180 billion by 2026, growing at a CAGR of 4.6%. This growth is driven by the increasing demand from various sectors, including manufacturing, oil and gas, and renewable energy. Selecting an appropriate motor power motor can significantly impact energy consumption, operational costs, and equipment longevity.

Therefore, understanding the specific requirements of your application, such as torque, speed, and load characteristics, is essential for making an informed decision. With a myriad of options available, this guide aims to elucidate the critical factors to consider when choosing the most suitable motor power motor tailored to your industrial needs.

When selecting the right motor power for your industrial applications, understanding your specific requirements is crucial. Each application may demand different power levels, speed controls, and torque capabilities, which can significantly influence the overall performance and efficiency of your operation. Begin by assessing the nature of your application: consider whether it involves continuous operation or intermittent usage, and identify the load characteristics that the motor will need to handle.

Moreover, various industries have distinct standards that dictate the motor requirements. For example, in manufacturing setups, motors may need to withstand harsh conditions and varying loads, while in logistics, the focus may be on achieving fast response times and high reliability. By meticulously analyzing these factors, you can determine whether you need an AC, DC, or stepper motor, and ensure that the selected motor not only meets the power requirements, but also aligns with your operational goals and environmental considerations.

Selecting the appropriate motor power rating for industrial applications is crucial for efficiency and reliability. Key factors to consider include the application type, load requirements, and duty cycle. According to a recent report by the NEMA, choosing the right motor can lead to energy savings of up to 30%. This significant reduction in operational costs underlines the importance of careful consideration during the selection process.

When assessing motor power ratings, it's essential to evaluate the torque requirements and the motor's efficiency class. Higher efficiency motors, such as IE3 or IE4 rated units, not only improve energy consumption but also extend the life of machinery. Additionally, considering the environmental conditions, such as temperature and humidity, will ensure that the selected motor operates within its optimal range.

Tip: Always calculate the required power by considering both the starting and running conditions of your application to avoid under-sizing or over-sizing the motor.

Tip: Consult with manufacturers to understand specific motor characteristics and options available for specialized applications, ensuring you select a motor that meets both current and future industrial needs.

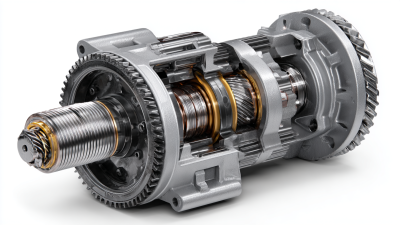

When choosing the right motor power for industrial applications, understanding the various types of motors available is crucial for ensuring optimal performance. Each motor type, such as AC, DC, and brushless motors, has distinct characteristics that make it suitable for specific industrial environments.

For instance, brushless DC (BLDC) motors are increasingly popular due to their efficiency and lower maintenance requirements, catering to industries with stringent energy-saving mandates. These motors are designed to fulfill the urgent need for energy conservation, especially in electric vehicles, where they provide a strong combination of performance and sustainability.

For instance, brushless DC (BLDC) motors are increasingly popular due to their efficiency and lower maintenance requirements, catering to industries with stringent energy-saving mandates. These motors are designed to fulfill the urgent need for energy conservation, especially in electric vehicles, where they provide a strong combination of performance and sustainability.

In addition to energy efficiency, performance metrics such as power output and torque are critical factors in motor selection. Analyzing different models reveals that while some motors excel in providing high torque for demanding applications, others are optimized for speed and efficiency. For instance, a motor with a peak output of 75 kW may deliver rapid acceleration, making it ideal for applications needing quick responses, while a different model may focus on sustained power generation over long durations.

Thus, when assessing motor options, it's important to consider the specific requirements of the application, including performance goals and operational conditions, to select the most suitable motor type.

When selecting a motor for industrial applications, energy efficiency and cost-effectiveness should be at the forefront of your decision-making process. Motors that are designed with energy efficiency in mind can significantly reduce operational costs, leading to substantial savings over time. Choosing the right power rating that aligns with your application's requirements is crucial; over-specifying a motor can lead to wasted energy, whereas under-specifying can cause inefficiencies and increased wear.

Tip 1: Always check the efficiency rating of the motor. Look for motors that meet or exceed the International Efficiency (IE) standards. Higher-rated motors typically consume less energy and provide better performance.

Tip 2: Consider the total cost of ownership, which includes purchase price, maintenance costs, and energy consumption over the motor's lifetime. Sometimes a slightly more expensive motor pays off in the long run due to lower energy costs.

Tip 3: Evaluate your operational processes to identify areas where motor usage can be optimized. Adjusting motor speeds or implementing variable frequency drives (VFDs) can enhance energy efficiency and further reduce costs.

When selecting the right motor power for your industrial applications, it's crucial to avoid common pitfalls that can lead to inefficiencies and increased costs. One of the most frequent mistakes is underestimating the required torque and power. Many buyers impulsively choose a motor based on its price or size, without fully understanding the demands of their equipment. This can result in a motor that is either overworked or insufficient, causing premature failures and costly downtimes.

Another mistake to watch out for is neglecting to consider the operating environment. Factors such as temperature, humidity, and potential exposure to chemicals can significantly impact motor performance and lifespan. Failing to account for these external conditions often leads to selecting a motor that may not withstand the operational stresses, resulting in further expenses for replacements or repairs. Thus, it's essential to assess both the mechanical and environmental requirements before making a decision on motor power solutions.

Office: (281) 855-2218

Copyright © 2025 Telco Intercontinental Corp. All rights reserved. Privacy Policy | Legal Disclaimer

Telco®, TelcoMotion®, and TelcoGreen® are registered trademarks of Telco Intercontinental Corp.