Main Menu

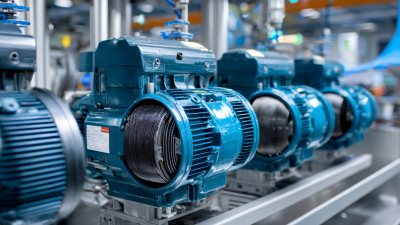

The search for the best motor power motor options is crucial for enhancing operational efficiency. Recent studies show that optimizing motor efficiency can lead to significant cost savings. According to the International Energy Agency, improving motor systems could save up to 440 terawatt-hours of energy annually. This reflects a global need for advanced technology in motor power motors.

Dr. Lisa Torres, a prominent figure in the motor industry, once stated, “Efficiency in motor power motors is not just a preference; it’s a necessity.” Her insights underscore the importance of energy-efficient choices in today’s competitive market. Businesses must understand the potential impact of selecting superior motor power motors.

However, selecting the perfect motor is not simple. Many companies overlook the long-term benefits of investing in high-efficiency motors. Data from the U.S. Department of Energy suggests that many existing systems operate at only 75% efficiency. A critical analysis of current operations can reveal inefficiencies that hinder progress. Therefore, exploring motor power motor options is vital for sustainable growth and energy conservation.

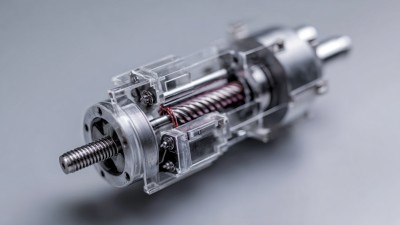

In industrial applications, choosing the right motor type is crucial for energy efficiency. Different motors have unique characteristics. For example, asynchronous motors are common due to their robustness. However, they may not always provide the best efficiency. Brushless DC motors offer higher efficiency, particularly in variable speed applications.

Tips: Consider the operational environment. Dusty or humid conditions can affect motor performance. Proper sealants can help maintain efficiency in challenging environments.

Another option is synchronous motors. They operate at a constant speed and can be more efficient at larger scales. However, installation and initial costs must be weighed against long-term savings. It's essential to analyze the specific requirements of your application.

Tips: Regular maintenance is key. Schedule inspections to identify potential issues early. This practice can prevent efficiency drops over time. Keep an eye on vibration and noise, as these can signal underlying problems.

When considering motor power options, the choice between AC and DC motors can significantly influence energy efficiency. AC motors often excel in larger applications. They tend to be simpler and require less maintenance. However, they can be less efficient at lower speeds. This can be a drawback in applications where precision matters.

On the other hand, DC motors provide excellent torque at low speeds. They are more versatile in speed control, making them popular in robotics and electric vehicles. Yet, they can suffer from higher wear and tear. Their brushes may need regular replacement, which can lead to increased downtime.

Ultimately, the decision should be informed by the specific application needs. An AC motor might save costs in big machinery. Meanwhile, a DC motor could offer superior performance for detailed tasks. Evaluating the requirements carefully can lead to a more efficient choice. Balancing efficiency with maintenance demands is key.

Motor efficiency is crucial for various applications. It determines how well a motor converts electrical energy into mechanical power. The NEMA standards play a significant role in this evaluation. These standards provide essential guidelines for understanding motor efficiency ratings. Compliance with these guidelines is important for manufacturers and users alike.

When selecting a motor, energy consumption cannot be overlooked. Motors with higher efficiency not only save energy but also reduce operational costs. NEMA offers different efficiency classes. These classes can influence decisions, especially in industries aiming for sustainability. However, not all high-rated motors are suitable for every application. Sometimes, efficiency comes at a higher initial cost.

Additionally, several factors can affect motor efficiency. Load conditions are essential; underloading or overloading affects performance. Ambient temperatures may also play a significant role. Installation factors must be considered too. Issues such as misalignment can reduce efficiency. Regular maintenance is necessary to ensure optimal performance. There is always room for improvement. Therefore, continuous reflection on motor choices and their operational contexts is critical.

This chart shows the efficiency ratings of different motor power options based on NEMA standards. The data illustrates how various factors influence motor efficiency.

Emerging technologies in motor design are revolutionizing efficiency across various industries. Recent studies by the Department of Energy show that advanced motors can achieve efficiency ratings as high as 96%. This is a significant improvement compared to traditional motors, which often operate at around 85%. Innovative designs, such as those employing integrated power electronics, are becoming more common.

One key trend is the use of artificial intelligence in motor control systems. AI can optimize motor performance in real time, adjusting parameters based on load and operating conditions. This adaptability is crucial for reducing energy consumption. However, many companies are still hesitant to adopt these technologies fully. They question costs versus long-term savings. Some businesses fear that initial investments might not be recouped quickly enough.

Another promising development is the use of new materials, such as silicon carbide semiconductors. These materials enhance the efficiency of power conversion. Reports indicate that motors using these materials can increase efficiency by 30% under specific conditions. Yet, there are challenges. Supply chains for these advanced materials can be unstable, leading to potential delays and increased costs. Balancing innovation with reliability remains a critical hurdle that the industry must overcome.

| Motor Type | Power Rating (kW) | Efficiency (%) | Weight (kg) | Application |

|---|---|---|---|---|

| Brushless DC Motor | 5 | 90 | 10 | Electric Vehicles |

| Induction Motor | 10 | 87 | 35 | Industrial Pumps |

| Step Motor | 1.5 | 85 | 3 | Robotics |

| Switched Reluctance Motor | 7.5 | 92 | 22 | HVAC Systems |

| Synchronous Motor | 15 | 95 | 50 | Large Fans |

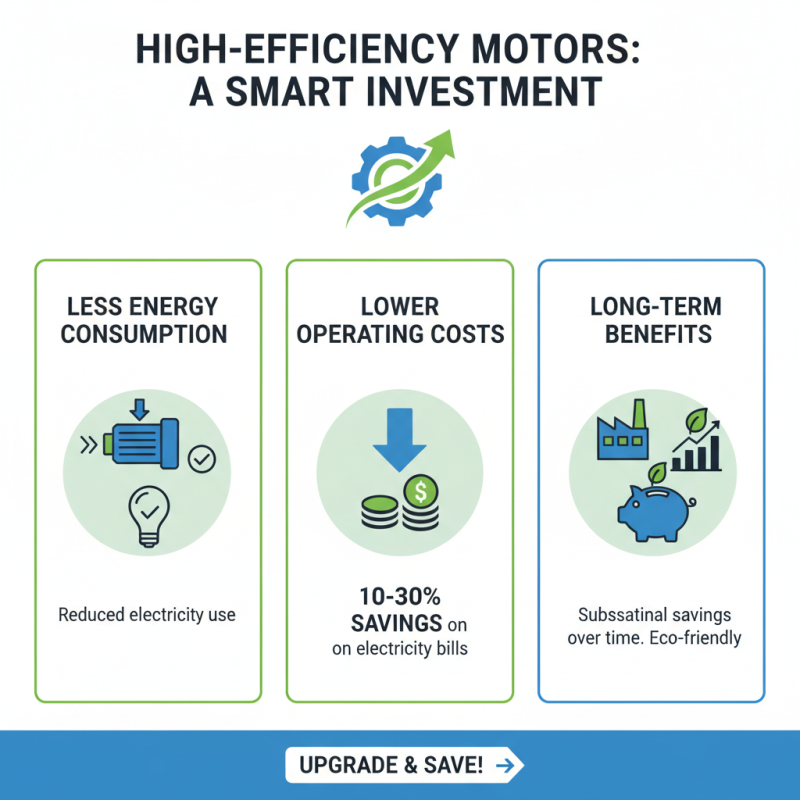

Upgrading to high-efficiency motors can be a game changer for many production facilities. These motors consume less energy, which translates into lower monthly bills. The initial investment may seem daunting, but the long-term savings can be substantial. Energy-efficient motors typically reduce electricity costs by 10% to 30%. This is significant in industries with high power demand.

Moreover, high-efficiency motors run cooler and are often more reliable. They require less maintenance, which can further reduce operational costs. However, transitioning to new technology isn’t without challenges. Workers may need training to manage new equipment effectively. Additionally, not all processes may benefit equally from an upgrade. Some facilities could face downtime during the transition, which might offset immediate gains. Carefully evaluating each department's energy use is critical.

When considering an upgrade, a detailed cost-benefit analysis is essential. Look at current energy bills versus the projected savings. Analyze the payback period of the investment. Production managers must weigh the pros and cons thoughtfully. Understanding how these motors impact overall efficiency requires a holistic view. Energy audits can help identify where upgrades will have the most significant impact.

Office: (281) 855-2218

Copyright © 2025 Telco Intercontinental Corp. All rights reserved. Privacy Policy | Legal Disclaimer

Telco®, TelcoMotion®, and TelcoGreen® are registered trademarks of Telco Intercontinental Corp.