Main Menu

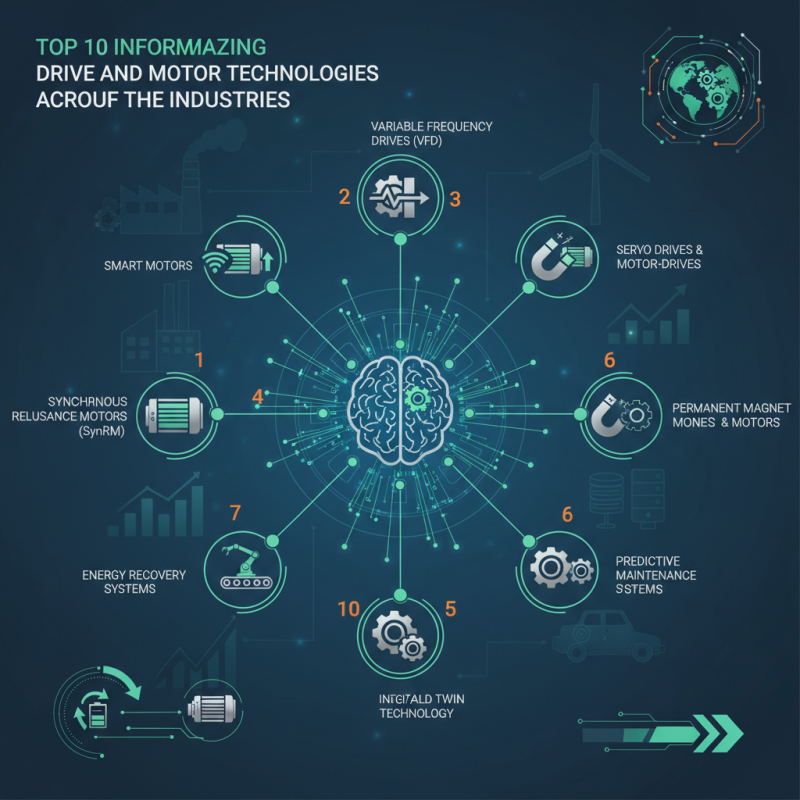

The drive and motor industry is undergoing significant transformation. Recent data from the International Electrotechnical Commission (IEC) reveals a projected annual growth rate of 6.9% for electric motor technologies through 2025. This surge reflects the increasing demand for energy-efficient solutions across various sectors. Experts claim that advanced drive and motor technologies are essential in improving productivity and reducing operational costs.

According to Dr. Emily Han, a leading authority in the field, "Efficient drive and motor systems are the backbone of modern industrial innovation." She emphasizes that companies adopting these technologies often achieve notable performance enhancements. For instance, industries leveraging smart motors report a 20% increase in efficiency.

However, challenges remain. Many companies struggle with outdated systems and lack the expertise to integrate new technologies effectively. The gap between existing capabilities and emerging demands calls for a reevaluation of strategies in the drive and motor sector. As industries embrace these innovations, they must confront not only the promise of advanced technologies but also the hurdles of implementation and adaptation.

Innovative electric drive technologies are transforming industrial practices. These advancements lead to efficient operations and enhanced productivity. Traditional motors are being replaced with more sustainable options. This shift is not just technical; it is changing mindsets across various sectors.

Electric drives can improve energy consumption. Many industries are witnessing a significant reduction in operational costs. However, not all adaptations yield immediate results. Some companies face challenges in integrating new technologies. Misalignment with existing systems may hinder progress and productivity. Adopting electric drives requires a cultural change that some firms overlook.

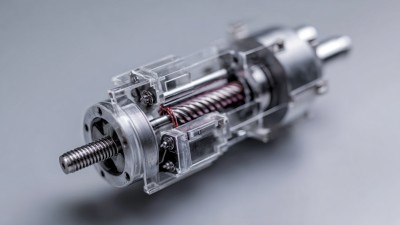

Innovations like variable frequency drives and smart motors are pivotal. They allow for better control and efficiency. Yet, workers may struggle to adapt to these advancements. Training is essential, but often inconsistent. Understanding the technology is vital for maximizing potential. While progress is underway, continuous evaluation is needed to ensure success and sustainability.

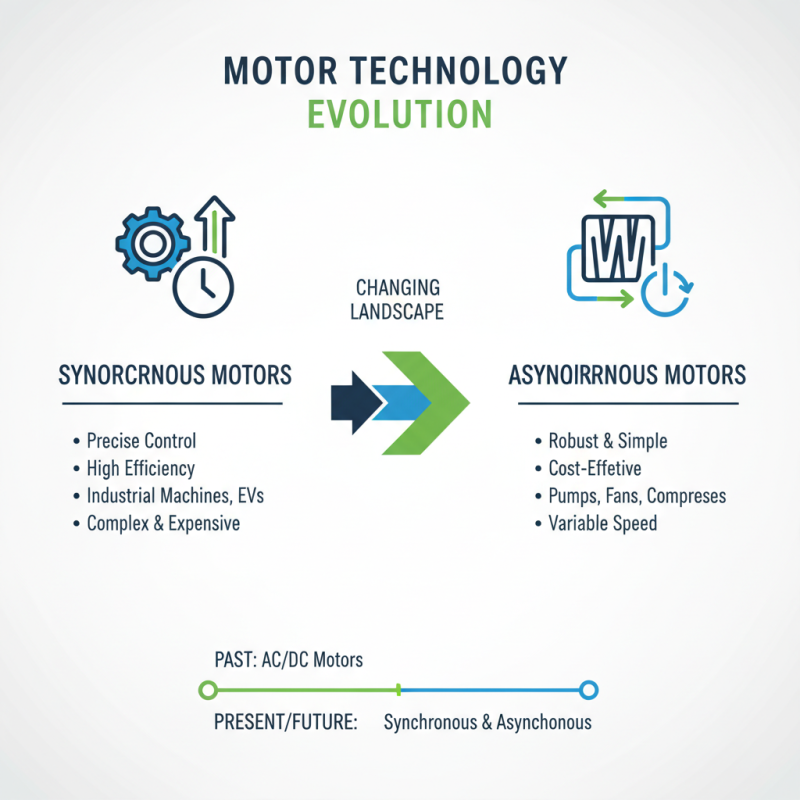

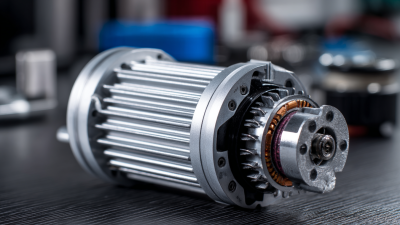

The landscape of motor technology is changing rapidly. Synchronous and asynchronous motors are at the forefront of these advancements. Synchronous motors operate in sync with the power supply frequency. This allows for precise control and high efficiency. Their applications span from industrial machines to electric vehicles. However, they tend to be more complex and expensive.

On the other hand, asynchronous motors are simpler and robust. They are widely used because of their lower cost and durability. These motors can handle varying loads well. But their efficiency drops under certain conditions. Both technologies have their pros and cons. Decision-makers must weigh their options carefully. The challenge lies in finding the right balance between cost and performance.

In recent years, new designs have emerged to tackle these issues. Innovative cooling techniques and better materials are enhancing performance. However, many industries hesitate to adopt these changes. The fear of high initial investment remains a barrier. Yet, the potential for long-term savings cannot be ignored. Exploring these challenges is crucial for future progress in motor technologies.

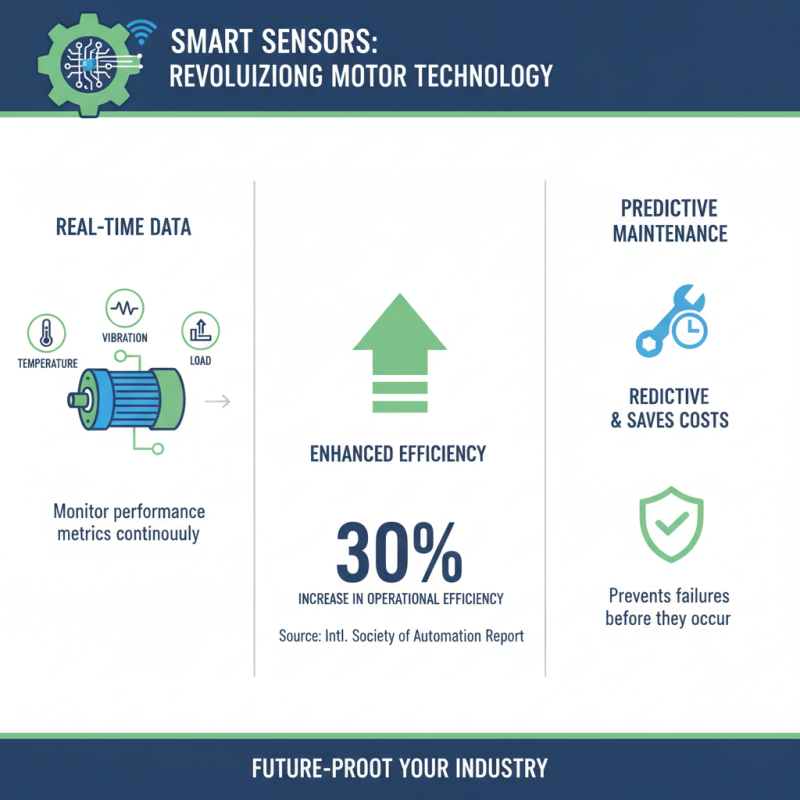

The integration of smart sensors into drive and motor technologies is a game-changer for numerous industries. Smart sensors collect real-time data about motor performance, enhancing efficiency. According to a report by the International Society of Automation, industries can see up to a 30% increase in efficiency when utilizing these technologies. Sensors monitor temperature, vibration, and load, enabling predictive maintenance. This reduces downtime and saves costs substantially.

However, the adoption of smart sensors is not without challenges. Data overload can occur, making it difficult to pinpoint actual issues. Inaccurate sensor readings can lead to misguided decisions. A study by the Institute of Electrical and Electronics Engineers suggests that nearly 25% of sensor-driven decisions may be flawed due to external variables. Companies must invest in data analytics to interpret sensor inputs effectively.

Despite these hurdles, the potential benefits are clear. Industries utilizing smart sensors in motor optimization reported up to 40% reduction in energy usage. The journey toward full integration remains complex. Continuous improvement and adaptation will be necessary for businesses to thrive in this evolving landscape.

The role of renewable energy in driving sustainable motor solutions is increasingly critical. Many industries are adopting electric motors powered by solar, wind, or hydro energy. This shift not only reduces carbon emissions but also promotes energy independence. Wind turbines are now major players, harnessing nature's force to generate electricity for electric vehicles and machinery.

Tips: Consider local renewable resources for powering your operations. Every small step counts in building a sustainable future.

Moreover, the integration of renewable energy sources in motor technologies enhances performance. Electric motors driven by solar energy exhibit impressive efficiency. However, the initial investment can be high. Organizations must weigh the long-term savings against upfront costs. Sometimes, old systems seem easier, but change is necessary for progress.

Tips: Evaluate your current energy practices. Understand how switching to renewable sources can benefit your bottom line.

Industries that embrace these innovations often face challenges. Gradual adaptation is crucial. Training staff on new technologies may require time and effort. While the transition can be daunting, the benefits of sustainability, cost-efficiency, and reduced environmental impact are undeniable.

The landscape of robotics and automation is rapidly changing. New drive systems are at the forefront of this revolution. These systems deliver precision, speed, and adaptability, but they also require careful consideration. Issues like power consumption and noise need attention.

Moreover, emerging trends are reshaping industries. For instance, electric motors are becoming smaller and lighter. This facilitates their use in compact robotics. At the same time, traditional pneumatic systems are facing pressure due to their inefficiency. It invites a critical reflection on how industries are adapting.

The integration of AI in drive systems is another exciting development. Smart systems offer predictive maintenance, enhancing uptime. However, reliance on technology raises concerns. What happens if these systems fail? As industries embrace innovation, they also confront new challenges, prompting deeper questions about sustainability and reliability.

Office: (281) 855-2218

Copyright © 2025 Telco Intercontinental Corp. All rights reserved. Privacy Policy | Legal Disclaimer

Telco®, TelcoMotion®, and TelcoGreen® are registered trademarks of Telco Intercontinental Corp.