Main Menu

In today's competitive industrial landscape, efficiency and productivity are paramount, driving manufacturers to seek out the best technology solutions. The 240 volt motor is becoming a cornerstone in various industrial applications due to its ability to provide high performance and energy efficiency. According to the latest report by the International Energy Agency (IEA), equipment operating at higher voltages can lead to a 20% reduction in energy consumption, significantly impacting operational costs over time.

Renowned electrical engineer Dr. Michael Anderson highlights the practical benefits of utilizing a 240 volt motor, stating, "Implementing a 240 volt motor not only enhances the operational efficiency of machinery but also contributes to a more sustainable energy profile for manufacturing plants." This insight underscores the importance of selecting appropriate motor specifications to maximize output while minimizing energy waste. By harnessing the advantages of a 240 volt motor, industries can opt for reliable and effective solutions that cater to both immediate and long-term operational goals.

Higher efficiency is a key advantage of using 240-volt motors in industrial applications. According to the U.S. Department of Energy, electric motors account for approximately 69% of the total electrical energy consumption in commercial and industrial sectors. By opting for a 240-volt motor, businesses can significantly reduce energy costs due to its superior efficiency. These motors often achieve efficiencies of over 90%, which translates to less wasted energy and lower operational costs. In a recent report by the National Electrical Manufacturers Association (NEMA), it was noted that upgrading to higher efficiency motors could lead to energy savings of 20-50% depending on the application and usage patterns.

Tips for maximizing the efficiency of 240-volt motors include regular maintenance and ensuring proper installation. Regularly inspecting the motor for wear and tear can prevent inefficiencies caused by mechanical issues. Additionally, ensuring the wiring and connections meet the required specifications will minimize energy losses. Another suggestion is to use variable frequency drives (VFDs) which allow for better control over the motor's speed and torque, further enhancing efficiency and operational flexibility.

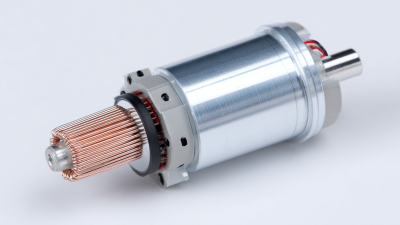

It's also notable that 240-volt motors often have a longer lifespan compared to their lower voltage counterparts. The robust design enables them to handle higher loads and varying operational conditions, which is essential in industrial environments. A report from the Electric Power Research Institute (EPRI) indicates that higher voltage motors typically experience less heat generation, reducing the wear on internal components and extending their operational life.

When evaluating the cost-effectiveness of 240 Volt motors versus lower voltage options in industrial applications, several key factors come into play. The initial investment in a 240 Volt motor may be higher, but its long-term operational efficiency justifies the expense. According to a report by the National Electrical Manufacturers Association (NEMA), 240 Volt motors typically offer a power factor of 0.9 to 0.95, significantly reducing energy consumption and operational costs over time. In contrast, lower voltage motors often operate at less efficient power factors, which can lead to higher energy bills and increased load on electrical systems.

Moreover, a study from the U.S. Department of Energy indicates that industrial facilities utilizing 240 Volt motors can achieve energy savings of up to 30% compared to their lower voltage counterparts. This is particularly important as energy prices continue to rise and sustainability goals become more pressing. Additionally, the lower starting current of 240 Volt motors minimizes strain on electrical infrastructure, reducing maintenance costs and extending the lifespan of both the motor and associated equipment. Thus, while the upfront cost may deter some companies, the ongoing savings and reliability make 240 Volt motors a wise investment for industrial operations.

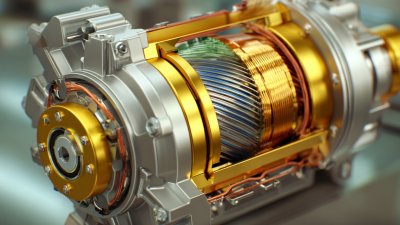

In high-power industrial settings, utilizing a 240 Volt motor offers significant enhancements in performance and reliability. These motors are designed to handle demanding tasks efficiently, delivering optimal torque and speed that are essential for heavy machinery operations. Higher voltage applications tend to reduce the current draw, which minimizes energy losses and heat generation, ultimately leading to prolonged equipment life and less frequent maintenance.

**Tip:** When selecting a 240 Volt motor, always consider the specific power requirements of your application. This ensures that the motor not only meets the demands of your process but also operates within its optimal load range for maximum efficiency.

Furthermore, the stability provided by 240 Volt motors translates to fewer interruptions in production cycles. The enhanced performance capabilities allow for better handling of variable loads and sudden shifts in operational demands, which is crucial for manufacturing environments that require consistent output.

**Tip:** Regularly monitor the motor’s performance and conduct preventive maintenance checks. This proactive approach can help identify potential issues before they escalate, ensuring sustained reliability in high-power industrial applications.

The adoption of 240 Volt motors in industrial applications is rapidly gaining traction, primarily due to their effectiveness in reducing energy consumption. These motors are designed to operate efficiently in settings where energy costs are a critical concern. By providing a higher voltage supply, 240 Volt motors can deliver increased power while maintaining lower current levels. This not only results in reduced losses associated with heat generation in wiring but also improves overall operational efficiency.

Furthermore, using 240 Volt motors can lead to significant savings in electricity costs for industrial facilities. Because these motors can handle heavier loads efficiently, they reduce the number of units needed for operation, which minimizes both initial investment and ongoing maintenance costs. Additionally, the enhanced torque and power output of a 240 Volt motor allow for smoother and more reliable operational performance, contributing to lower energy expenditure throughout the entire production process. Consequently, industries looking to optimize their energy usage and operational costs are increasingly turning to 240 Volt motors as a viable solution.

The use of 240 Volt motors in industrial applications offers significant safety and compliance advantages that contribute to a more secure working environment. One of the primary benefits lies in the lower risk of electric shock. Compared to standard 120 Volt systems, 240 Volt configurations reduce the current flowing through a circuit for a given power output, which inherently decreases the chances of dangerous surges. This is particularly important in industrial settings where large machines are used, minimizing risks for operators and maintenance personnel.

Additionally, using 240 Volt motors enhances compliance with industry safety standards and regulations. Many regulatory bodies mandate specific voltage requirements to ensure safe operation within workplaces. By opting for 240 Volt motors, facilities are better positioned to meet these guidelines promoting a culture of safety and accountability. Furthermore, maintaining compliance with voltage specifications can lead to lower insurance premiums, as insurers recognize the reduced risk associated with well-designed electrical systems.

Office: (281) 855-2218

Copyright © 2025 Telco Intercontinental Corp. All rights reserved. Privacy Policy | Legal Disclaimer

Telco®, TelcoMotion®, and TelcoGreen® are registered trademarks of Telco Intercontinental Corp.